Punch Press Frame Impacts Stamping Efficiency & Accuracy

As a cornerstone of modern manufacturing, the structural rigidity, stability, and eccentric load resistance of a press (stamping press) directly determine machining precision, die service

Smart touchscreen controls and automation compatibility enable visualized production management.

Maintenance-free designs and robust frameworks guarantee low downtime and extended service life.

Energy-saving, low-noise operation, and optimized material utilization empower eco-friendly production.

Turnkey delivery, comprehensive training, critical spares kits, and 24/7 global support

With years of industry experience, Changduan Servo Press Company has become a leader in the press manufacturing field. We specialize in providing high-performance servo presses, pneumatic presses, and hydraulic presses to meet your diverse production needs.

Our flagship product, the servo press, represents the future of stamping technology. It is a cutting-edge machine designed for flexible manufacturing, highly regarded for its outstanding performance and remarkable energy efficiency. Unlike traditional presses, the servo press integrates a human-machine interface (HMI), programmable logic controller (PLC), servo drives, and motors into an advanced intelligent servo control system, eliminating the need for a conventional clutch/brake system.

We specialize in manufacturing high-precision servo presses—from open-back single-point to split-frame straight-side double-point and four-point models—with capacities spanning 5 to 4,000 tons. We also deliver customized solutions tailored to your unique industrial requirements.

Split Closed Double/Four Point Precision Electric Servo Press 400~4000 TONS

Elbow Type Pull-Down Four-Point High-Speed Precision Electric Servo Press 5~500 TONS

High-Efficiency and Precision Servo Drawing Special Production Line

We are developed in collaboration with industry leaders like Swiss RUSKIN and Yamada Machinery. Our presses are perfect for a wide range of applications, including new energy battery production. We also offer turnkey projects and complete automated production lines to deliver a seamless, ready-to-use solution for your business.

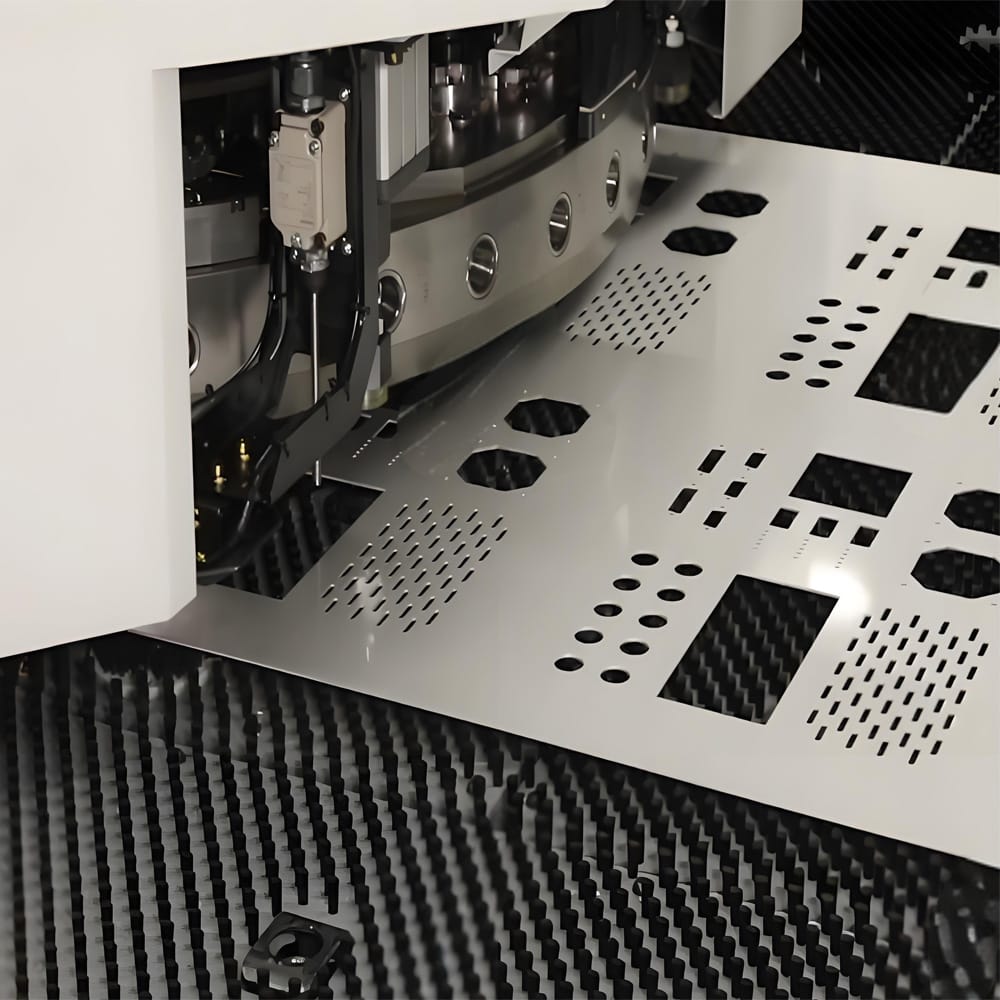

Our presses excel at a wide range of tasks, from common processes like punching, blanking, bending, and deep drawing to more specialized applications. They are designed to handle complex jobs, including the precise punching of irregular and variable-diameter holes and the accurate control of bending speed and pressure. Our machines are also widely used for advanced techniques such as flanging, leveling, coining, and forging.

Our servo presses offer unparalleled precision, allowing you to customize stroke settings and power output to achieve flawless, consistent results for every project. Thanks to the controllable motion curve, our machines deliver a level of precise control ideal for jobs with the highest requirements for precision and surface quality.

By minimizing waste and preventing equipment damage through precise control, our servo presses not only improve product yield but also significantly reduce your operational costs.

With a variety of flexible control modes and real-time monitoring, our presses can adapt to complex production demands, from simple stamping to intricate high-precision tasks.

High-rigidity frame (25–800 tons) with ±0.01mm precision and 15–25% energy-saving design. CE/ISO-certified, supports PLC automation and multi-station setups for automotive/electronics stamping. Rapid mold change and custom solutions available.

High Precision Hot Die Forging Pneumatic Stamping Press 800~16000 TONS

Open Single-Point Precision Pneumatic Stamping Press 25~400 TONS

Open Double-Point Precision Pneumatic Stamping Press 110~400 TONS

Closed Single-Point Precision Pneumatic Stamping Press 125~315 TONS

Closed Single-Point Precision Pneumatic Stamping Press 125~630 TONS

Split Closed Two-Point Precision Pneumatic Stamping Press 315~800 TONS

We are committed to delivering exceptional value to global clients through a suite of tailored advantages designed to streamline your production and ensure peace of mind.

Witness live production & assembly! Join factory tours to see your machine being built — concrete proof of our record-breaking delivery capability.

Start stamping in hours, not weeks. Every press ships fully assembled, with 10,000+ cycle validation tests, pre-installed CE/OSHA certifications, and calibrated servo controls. Zero commissioning delays.

⚡40-60% Lower Energy Consumption vs. traditional presses. 🎯±0.01mm Repeatable Precision with adaptive slide motion control. 🔧Reduced Gear/Wear Part Stress by 30%

Opt for certified engineer-led commissioning or access our 24/7 multilingual video portal covering setup, maintenance, and servo optimization techniques.

Slash downtime risks. Our IoT-connected presses enable real-time remote diagnostics, resulting in a 70% drop in resolution times.

Defend against unplanned stops. Receive a customized spare parts kit with high-wear servo components.

As a cornerstone of modern manufacturing, the structural rigidity, stability, and eccentric load resistance of a press (stamping press) directly determine machining precision, die service

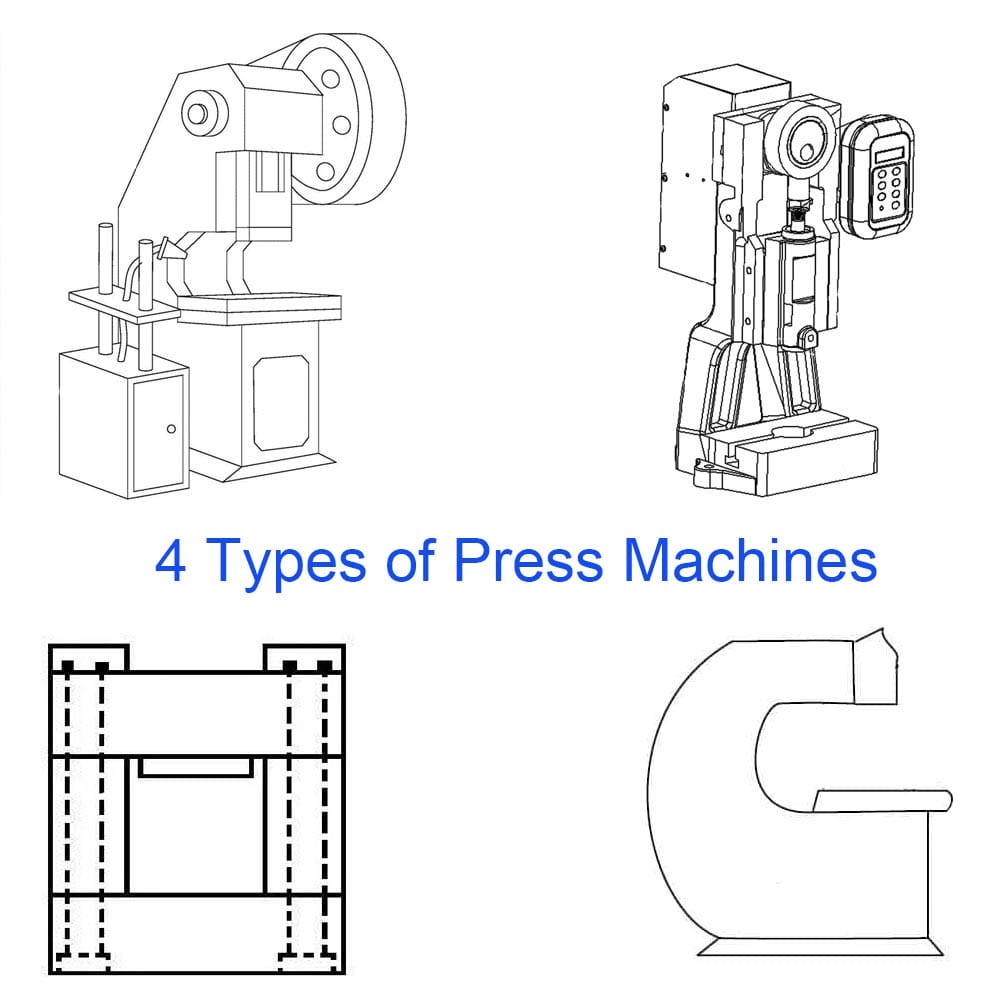

Choosing a suitable press for your factory can boost efficiency and save costs.

Industrial press machines form the backbone of mass production across aerospace, automotive, and electronics sectors.

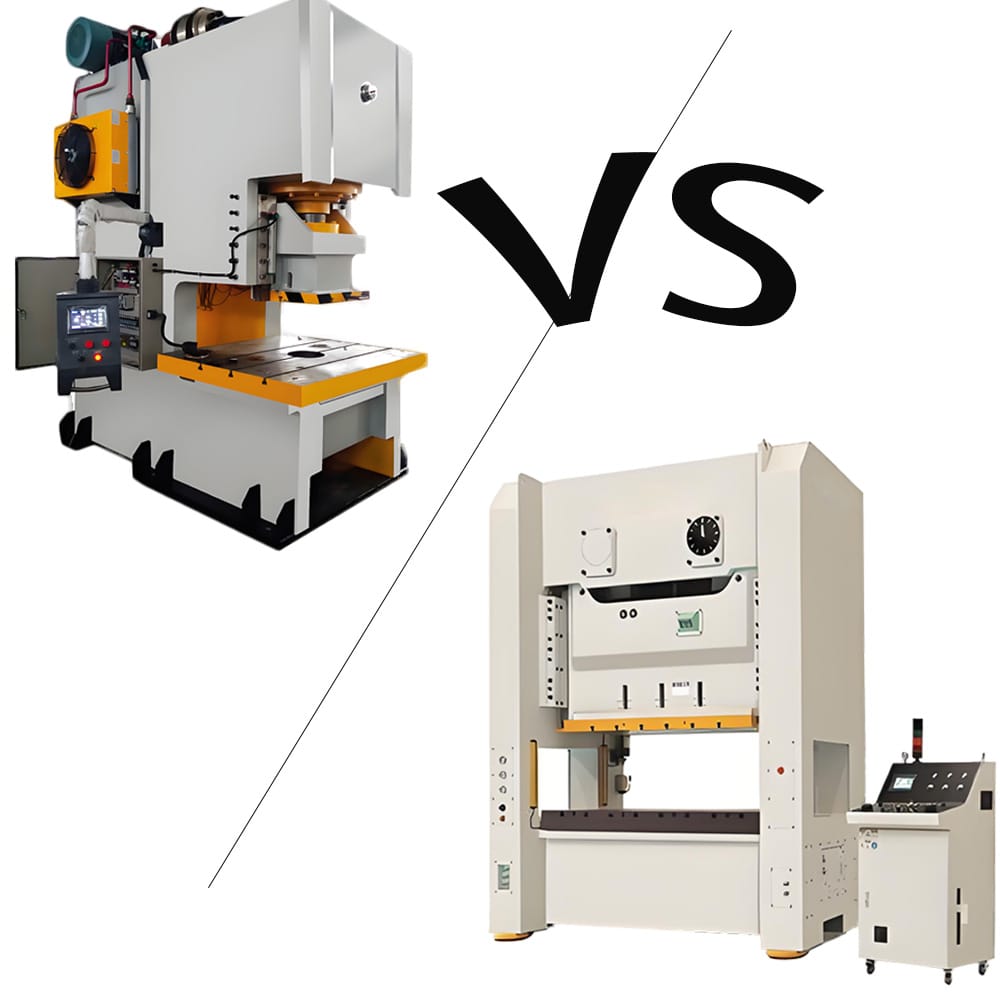

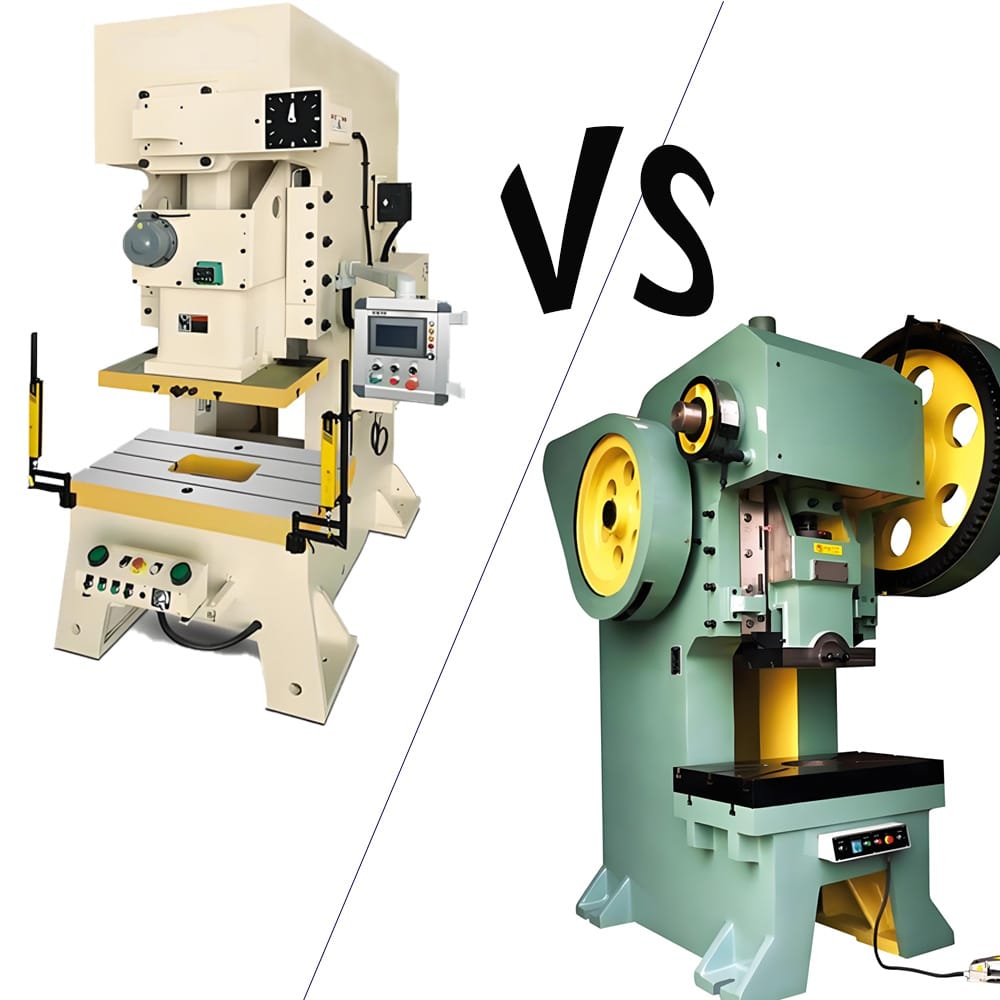

Discover the key differences between servo presses and mechanical presses, including precision, energy efficiency, and cost. Learn which machine optimizes your stamping process.

Precision, efficiency, and adaptability are non-negotiable in today’s fast-paced manufacturing landscape.

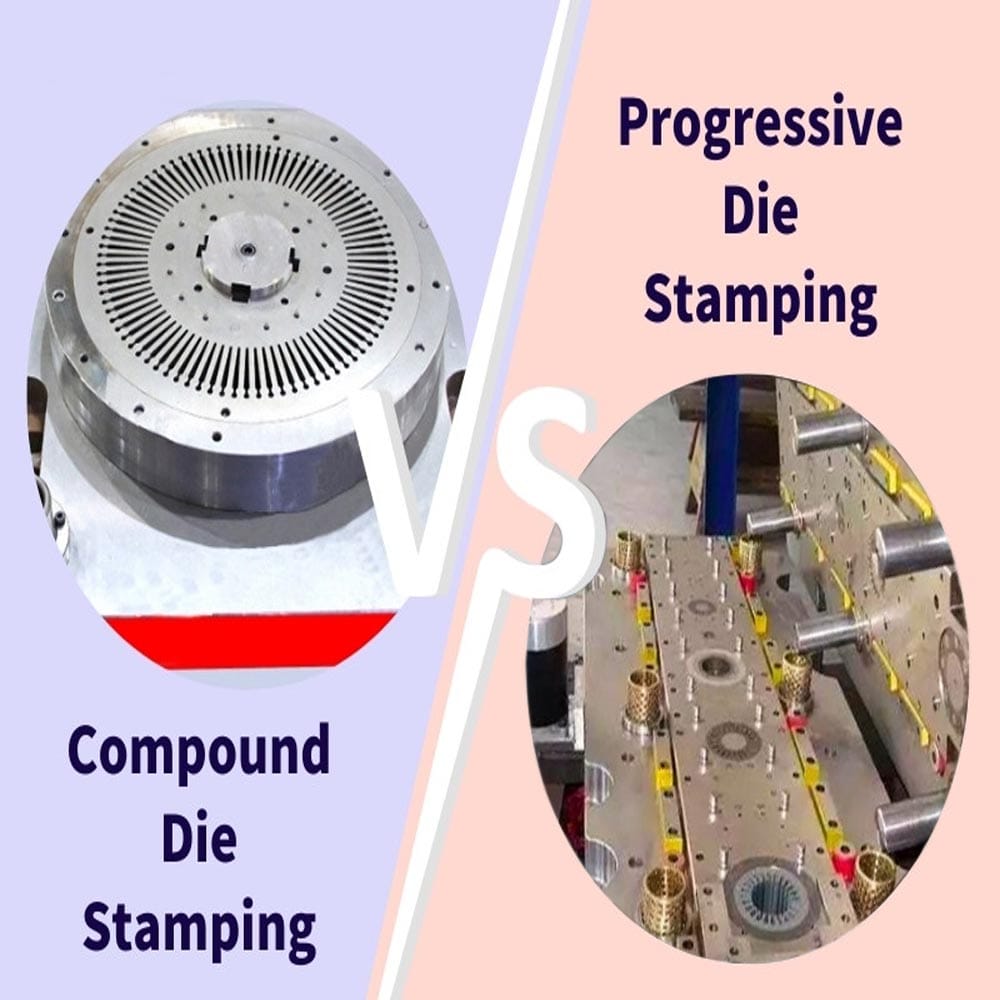

While single-stage presses are flexible, they require multiple setups and manual handling, which slows down production. To solve this, engineers developed compound die presses and

Fill out the form below, and we will be in touch shortly.