The traditional classification is mainly concentrated in mechanical, hydraulic, and pneumatic systems, but today’s innovative landscape servo punch press is far ahead in many aspects. Let’s take a look!

A press machine, also known as a forming press or a stamping press, is a heavy-duty industrial press. During the forming process, it applies tremendous, controllable pressure to plastically deform or separate a mold on sheet, strip, tube, or profile, producing a workpiece or semi-finished product of the desired shape and size (e.g., changing or adjusting the dimensions of steel, aluminum, or other materials). Put, its primary purpose is to “punch” and “press” thin sheet materials, making it widely used in the manufacturing industry.

Press machines come in various types but share core components: a rigid frame/base and a punch and die set, where the punch is mounted on the moving ram and the die is secured to the stationary platen (worktable). The machine applies controlled force to sheet metal through a power system that drives the ram downward.

Most assembly presses consist of three fundamental parts:

Frame: Provides structural integrity.

Ram (Slide): Delivers vertical pressing force.

Platen (Bolster Plate): Supports the die and workpiece.

We specialize in servo-electric and pneumatic presses, while offering custom hydraulic solutions like our recently delivered 4-column dual-cylinder hydraulic press featuring multi-point synchronization control for uniform pressure distribution.

Drive Mechanism: Lever/screw mechanism amplifies human force

Applications: Lab sample prep, repair workshops, low-volume sheet metal bending

Advantages:

✓ Zero energy consumption

✓ Portable & compact

✓ Ultra-low operating cost

Disadvantages:

✘ Max. 5-ton capacity

✘ Low efficiency

✘ Operator skill-dependent

Drive Mechanism: Servo motor drives ball screw with PLC-programmed motion curves

Applications:

Precision electronics blanking

Medical device forming

Progressive die stamping

Advantages:

✓ ±0.01mm repeat accuracy

✓ 30-60% energy savings

✓ Programmable stroke/speed

✓ Under 75dB noise level

Disadvantages:

✘ Higher initial investment

✘ Requires specialized maintenance

✓ Mitigation:

Drive Mechanism: Compressed air drives the cylinder piston for linear force

Applications:

PCB punching

Plastic riveting

Light-duty press-fitting

Advantages:

✓ 500+ strokes/minute

✓ Explosion-proof operation

✓ Minimal maintenance

✓ Ideal for low-tonnage tasks

Disadvantages:

✘ Noise >85dB

✘ ±5% force fluctuation

Drive Mechanism: Motor-driven pump → Valve-controlled oil flow → Cylinder pressure

Applications:

Automotive beam forming

Powder metallurgy compaction

Composite lamination

Advantages:

✓ Full-stroke constant force

✓ Overload protection

✓ 5,000+ ton configurations

✓ Optimized for deep drawing/heavy forming

Disadvantages:

✘ Oil temperature sensitivity

✘ Slower cycle times

✘ Potential leakage risks

Drive Mechanism: Motor → Flywheel → Clutch → Crankshaft → Ram linear motion

Applications:

High-volume standard part blanking

Hardware progressive die production

Advantages:

✓ 100+ SPM operation

✓ Simple mechanical design

✓ Lower acquisition cost

Disadvantages:

✘ Full tonnage only at bottom dead center

✘ High inertia (emergency stop challenges)

✘ Significant vibration/noise

| Process | Inherent Limitation | Servo Press Solution | Pneumatic Press Solution | Hydraulic Press Solution |

|---|---|---|---|---|

| Punching | High tonnage needed for thick materials | ✓ High-torque low-speed capability | ✘ Limited to light-duty | ✓ Full-stroke constant force |

| Accuracy loss in dense patterns | ✓ Closed-loop position compensation | ✓ Air cushion vibration reduction | ✘ Thermal drift affects precision | |

| Stamping | High tooling cost/slow changeover | ✓ Quick-die change + program recall | ✓ Simple die compatibility | ✓ Wider process adaptability |

| Low flexibility | ✓ Programmable force profiles | ✘ Basic forming only | ✓ Infinite pressure adjustment | |

| Bending | Springback challenges | ✓ Real-time depth compensation | ✘ Force fluctuations | ✓ Dwell pressure minimizes rebound |

| Low complex-curve efficiency | ✓ Multi-axis 3D bending capability | ✘ Straight-line bends only | ✓ Slow-speed precision forming | |

| Forging | Requires auxiliary heating | ✘ No thermal control | ✘ Unsuitable for hot work | ✓ Heated platen integration |

| Die thermal stress damage | ✓ Cold forging reduces fatigue | ✘ Not applicable | ✓ Optional die cooling systems | |

| Deep Drawing | Wrinkling/tearing defects | ✓ Multi-stage speed control | ✘ Insufficient force causes cracks | ✓ Blank holder force optimization |

| Multi-stage draws required | ✓ Single-step high-ratio forming | ✘ Shallow draws only | ✓ Long-stroke multi-draw capacity | |

| Embossing | Poor curved surface adaptation | ✓ 6-axis workpiece positioning | ✘ Rigid impact damages contours | ✓ Soft-touch pressure application |

| Shallow relief wear | ✓ Precision force extends die life | ✓ High cycles distribute wear | ✓ High pressure for deep reliefs | |

| Coining | Inconsistent manual force | ✓ Servo-driven force replacement | ✓ Air pressure consistency | ✘ Overkill for precision work |

| Operator skill dependency | ✓ Automated program eliminates variance | ✓ Simplified parameter setting | ✘ Complex operation requires training |

Punch presses are primarily used for metal stamping, including punching, blanking, shearing, bending, folding, stretching, deep drawing, flanging, curling, bulging, shrinking, coining, finishing, riveting, and press-fitting of steel, aluminum, copper, and other metal sheets and strips. Punch presses are also widely used for forming and cutting non-metallic materials. These applications typically require lower tonnage and relatively simple processes.

Working Principle:

Creates holes or cuts contours through shearing action between the punch and the die.

Applications:

Ventilation holes in electrical enclosures

Perforated screens for filtration systems

Decorative cutouts in signage

Advantages:

✓ Rapid multi-hole processing capability

✓ Clean cuts without burrs

✓ Quick die changeovers

Limitations:

✘ High-tonnage required for thick materials

✘ Potential accuracy loss in dense punching patterns

Working Principle:

Shapes or cuts metal using compressive force between matched dies.

Applications:

Automotive body panel forming

Appliance housing production

Coin and medal minting

Advantages:

✓ Compound operations per stroke

✓ Complex 3D geometry capability

✓ High material utilization

Limitations:

✘ High tooling investment

✘ Limited flexibility (die-dependent)

Working Principle:

Bends sheet metal by pressing it between upper and lower dies.

Applications:

Electronic chassis fabrication

Architectural framework bending

Pipe support manufacturing

Advantages:

✓ Adjustable bend angles

✓ Capable of long-part processing

✓ Surface integrity preservation

Limitations:

✘ Springback compensation required

✘ Low efficiency for complex curves

Working Principle:

Reshapes heated metal under sustained pressure within closed dies.

Applications:

Engine crankshaft forging

Hand tool manufacturing

Aerospace titanium components

Advantages:

✓ Enhanced metallurgical properties

✓ Reduced machining requirements

✓ Near-net-shape production

Limitations:

✘ Auxiliary heating systems are needed

✘ Extreme thermal stress on dies

Working Principle:

Forms sheet metal into hollow shapes via radial tensile stress.

Applications:

Kitchen sink manufacturing

Battery case production

Pressure vessel forming

Advantages:

✓ High depth-to-diameter ratios

✓ Seamless part integrity

✓ Uniform wall thickness control

Limitations:

✘ Wrinkling/tearing risks

✘ Often requires multi-stage processing

Working Principle:

Creates surface relief patterns through controlled plastic deformation.

Applications:

Decorative leather texturing

Anti-slip tile patterning

Packaging surface enhancement

Advantages:

✓ Aesthetic/functional surface improvement

✓ Non-destructive material processing

✓ High-speed single-hit operation

Limitations:

✘ Shallow details prone to wear

✘ Limited curved surface adaptability

Working Principle:

Generates linear force through a rotational screw mechanism.

Applications:

Precision jewelry coining

Ceramic blank compaction

Laboratory sample preparation

Advantages:

✓ Operator-controlled pressure

✓ Hydraulic-free clean operation

✓ Simple mechanical reliability

Limitations:

✘ Output consistency varies

✘ Operator skill-dependent

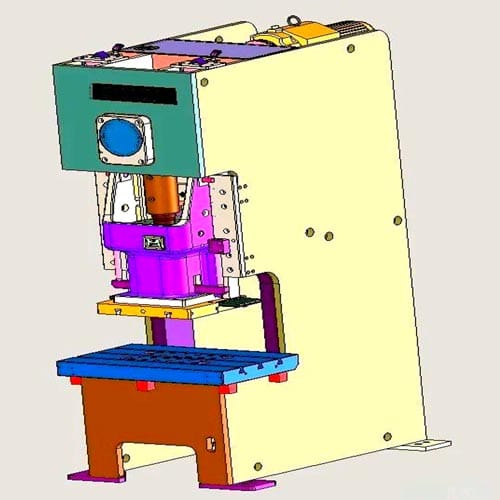

Characteristics:

Open-front construction with “C” shaped profile

Self-contained bed/crown assembly

Applications:

✓ Straightening ✓ Light blanking ✓ Assembly

Characteristics:

Pivoting C-frame (15°-30° tilt capability)

Gravity-assisted scrap ejection

Applications:

✓ Progressive stamping ✓ High-speed piercing

Characteristics:

Twin vertical columns + crown/bed box construction

Guided slide movement

Applications:

✓ Automotive panel stamping ✓ Precision coining

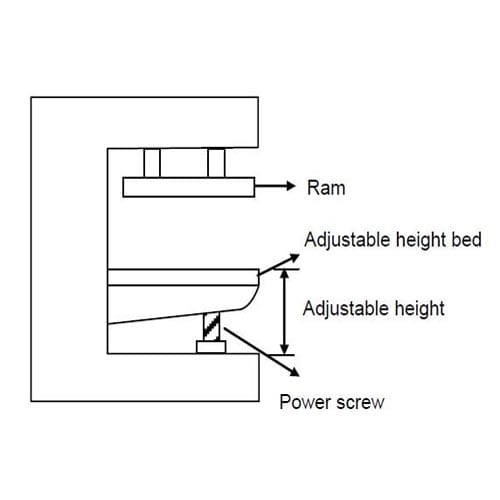

Characteristics:

Dual vertical cylinders + movable platen

Adjustable bed height

Applications:

✓ Compression molding ✓ Rubber vulcanizing

Related Read: C Frame Press vs H Frame Press

Regardless of frame design (C-type, straight-side, etc.), the ram delivers controlled force while the frame provides critical stability to the platen – ensuring precision during metal forming operations. Advanced models integrate PLC-controlled automation interfaces for seamless integration into production lines.

Our press machines can address the shortcomings of traditional processes. Our main servo + pneumatic solutions have significant advantages in lightweight and high-precision areas, while our hydraulic customization capabilities can complement the needs of heavy industrial scenarios. For example, we can use servo-hydraulic hybrid systems or servo-pneumatic hybrid systems to address the shortcomings of a single process, thus ensuring both precision and efficiency. At the same time, targeted selection should also be based on material properties (thickness/ductility), production requirements, and precision level. If you are not sure how to choose, don’t hesitate to get in touch with us.

Fill out the form below, and we will be in touch shortly.