Servo Presses

Electric Die Height Adjustment System

Control the die height by electric power, enhancing automation and machining accuracy.

Digital Die Height Indicator

Showing die height values in servo presses, aiding in accurate press operations and higher efficiency.

Slide and Die Weight Balancer

balances the weights of the slide and the die in a press machine, helping to improve the stability and performance of the press operation.

Rotary Encoder

Converts the angular position or motion of a rotating shaft into electrical signals, which can be used to measure speed, position, and direction in various mechanical and electrical systems.

Electromagnetic Stroke Counter

Uses electromagnetic mechanisms to count the number of strokes in machinery, enabling accurate tracking of operational cycles in industrial applications.

Mis-feed Detection Interface Port

Serves as a connection point for components related to detecting improper material feeding, allowing the machine to identify and respond to misfeeding situations.

Stepless Speed Control System

Enables continuous and seamless adjustment of the rotational speed of a machine, providing flexibility in operation to meet different process requirements without discrete speed steps.

Pneumatic die cushion device

Uses compressed air to generate a cushioning force that supports and controls the movement of the die during stamping operations, ensuring stable and accurate forming of workpieces.

Quick die change device (Q.D.C.)

Rapidly and efficiently swap dies in a machine, significantly reducing the downtime associated with die replacement and enhancing overall production efficiency.

Preset counter

Allows users to set a specific number in advance, and it counts events until the preset value is reached, often used to control processes when a certain number of operations need to be completed.

Part Ejector

A mechanism that forcefully expels finished or semi-finished parts from a mold, die, or machining fixture, ensuring smooth removal of parts for further processing or collection.

Automatic Feeding System (Feeder, Coil Stand, Straightener)

Automatically supplies and straightens coil materials to the production line with precise control, ensuring a continuous and efficient feeding process for manufacturing operations.

Robotic Arm

Automatically load and unload materials, precisely position workpieces for punching operations, and handle the finished parts, thereby improving production efficiency, reducing labor costs, and enhancing the accuracy and quality of punching processes.

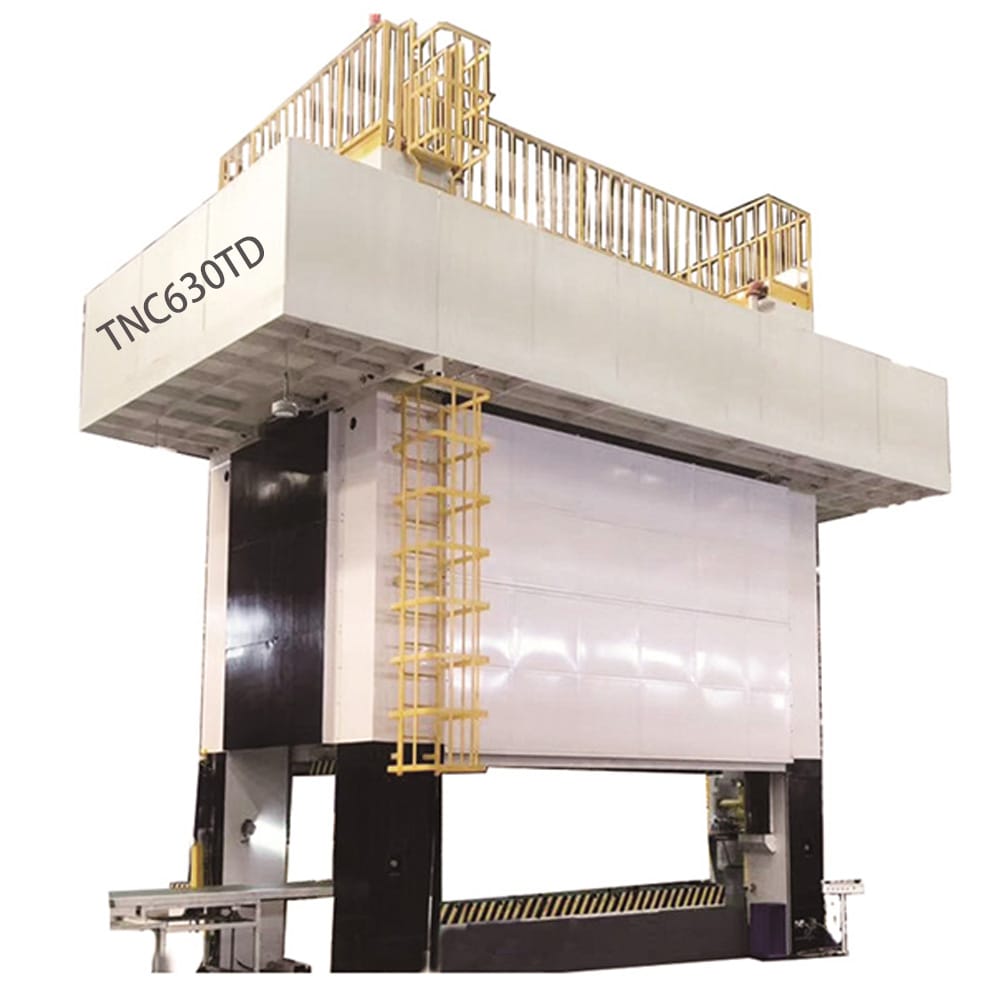

TNB-EX (25-400T), NB-EX Series (25~300T), TNB-EO Series (80~800T), TNC-EO Series (200~2000T), TNC-RO Series (110~1000T), TNC-TD/FD Series (400~4000T), TNB-WO Series (5-500T), TNB-HO Series (45-660T). We also have different model pneumatic punch presses. If you have any questions, please contact us.

25tons, 45tons, 60tons, 80tons, 110tons, 160tons, 200tons, 250tons, 300tons, 400tons

25tons, 45tons, 60tons, 80tons, 125tons, 160tons, 200tons, 250tons, 300tons

80tons, 110tons, 160tons, 200tons, 250tons, 300tons, 400tons, 600tons, 800tons

200tons, 250tons, 300tons, 400tons, 500tons, 600tons, 800tons, 1000tons, 1250tons, 1600tons,2000tons

110tons, 160tons, 200tons, 300tons, 400tons, 500tons, 600tons, 800tons, 1000tons

400tons, 630tons, 800tons, 1000tons, 1250tons, 1600tons, 2000tons, 2500tons, 3300tons, 4000tons

5tons, 15tons, 25tons, 35tons, 45tons, 65tons, 110tons, 125tons, 150tons, 200tons, 250tons, 300tons, 400tons, 500tons

45tons, 66tons, 88tons, 150tons, 220tons, 330tons, 440tons, 550tons, 660tons

If you have any questions about servo press machine, please feel free to contact us

Fill out the form below, and we will be in touch shortly.