The Precision Electric Servo Press TNB-EX Series combines high precision, energy efficiency, safety, ergonomic design, and versatility to deliver exceptional performance in modern manufacturing. With advanced features such as a high-rigidity frame, servo drive system, and automation compatibility, this press is ideal for high-quality stamping and forming applications across various industries.

Ensures consistent precision in part manufacturing, improving product quality.

Reduces scrap rates and enhances repeatability for tight-tolerance applications.

Low power consumption reduces operational costs and supports sustainable manufacturing practices.

Complies with global environmental standards, minimizing carbon footprint.

Meets international safety standards (e.g., JIS Level 1, CE compliance) for safe operation.

Integrated safety features such as light curtains and emergency stop systems.

User-friendly controls and ergonomic design reduce operator fatigue and improve productivity.

A centralized lubrication system ensures smooth operation and extends the lifespan of the components.

Suitable for a variety of industries, including automotive, electronics, and appliance manufacturing.

Capable of handling diverse materials, from thin-gauge metals to high-strength alloys.

| Model | TNB25EX | TNB45EX | TNB60EX | TNB80EX | TNB110EX | TNB160EX | TNB200EX | TNB250EX | TNB300EX | TNB400EX |

| Capacity (kN) | 250 | 450 | 600 | 800 | 1100 | 1600 | 2000 | 2500 | 3000 | 4000 |

| Stroke (mm) | 100 | 120 | 150 | 100 | 200 | 200 | 200 | 250 | 250 | 250 |

| Continuous Frequency | 2 – 100 | 2 – 150 | 2 – 135 | 2 – 120 | 2 – 90 | 2 – 60 | 2 – 70 | 2 – 60 | 2 – 50 | 2 – 40 |

| Inching Frequency (spm) | 210 | 190 | 170 | 150 | 120 | 80 | 80 | 60 | 50 | 40 |

| Maximum Inching Height (mm) | 400 | 420 | 420 | 340 | 400 | 460 | 460 | 500 | 500 | 500 |

| Mold Height Adjustment (mm) | 50 | 60 | 60 | 75 | 80 | 80 | 100 | 110 | 110 | 120 |

| UP Platform Area (mm) | 470*350 | 560*400 | 700*470 | 700*470 | 910*560 | 960*650 | 1130*650 | 1200*700 | 1400*800 | 1600*900 |

| Down Platform Area (mm) | 800*670 | 840*700 | 1000*700 | 1000*750 | 1150*910 | 1250*960 | 1400*1150 | 1500*1250 | 1680*1450 | 1800*1650 |

| Distance from Slider center to fuselage (mm) | 205 | 235 | 255 | 280 | 335 | 405 | 415 | 425 | 425 | 495 |

| Shank Hole (mm) | φ40 | φ45 | φ50 | φ50 | φ50 | φ65 | φ65 | φ65 | φ65 | φ65 |

| Slider adjustment mode | – | Manual adjustment | – | – | – | – | – | – | Electric adjustment | – |

| Working air pressure (Mpa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Punch precision | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level | JIS 18th level |

| Mold pad capacity (ton) | – | 2.3 | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | 14 | 14 |

| Mold pad stroke (mm) | – | 50 | 70 | 70 | 60 | 80 | 100 | 100 | 100 | 100 |

| Effective area of mold pad (mm²) | – | 250*230 | 300*300 | 400*310 | 450*350 | 600*420 | 620*450 | 650*480 | 700*480 | 750*480 |

FAQS For the Servo Press Industry

TNB-EX is ideal for heavy-duty industrial applications requiring higher tonnage (25–400 tons) and extended production runs. Its rigid C-frame design and advanced vibration control ensure stability for large-scale manufacturing.

Higher capacity range (up to 400 tons) for demanding stamping tasks.

Standard photoelectric safety device and machine tool isolators for enhanced operational safety and reduced machine wear.

Larger mold pad capacity (up to 14 tons) and extended stroke options for complex forming processes.

Yes. It includes a miscellaneous detection interface and pneumatic blow device as standard, making it compatible with advanced automation systems like robotic arms and quick die change (Q.D.C.) units.

Its Grade JIS 1-certified accuracy is backed by a high-rigidity frame and electric mold height adjustment, minimizing deformation even under maximum load.

A servo press (also called an electric servo press) is a high-precision stamping machine powered by a servo motor + control system. It directly drives the crankshaft or linkage mechanism without traditional components like flywheels, clutches, or brakes, enabling programmable control over stroke, speed, and force for energy-efficient and flexible operations.

Which Press is right for your needs?

Click here to read our detailed comparison blog and discover which press is the best fit for your production needs!

Feature | Servo Press | Hydraulic Press |

|---|---|---|

Precision |

±0.01mm (JIS Grade 1) |

±0.1mm (lower due to fluid compressibility) |

Speed |

High (up to 1200 SPM) |

Low to medium (typically 10-60 SPM) |

Energy Efficiency |

30~60% energy savings |

High energy consumption |

Flexibility |

Programmable stroke,speed,and force |

Limited motion control |

Maintenance |

Low (no hydraulic oil or seals) |

High (frequent oil and seal changes) |

Noise Level |

Quieter (10~15dB lower) |

Louder (pump and fluid noise) |

Our servo press adopts direct servo motor drive technology, offering the following advantages over traditional mechanical presses:

✅Energy savings of over 30% (no flywheel idling losses)

✅ Repeat positioning accuracy of ±0.01mm (certified to JIS Grade 1)

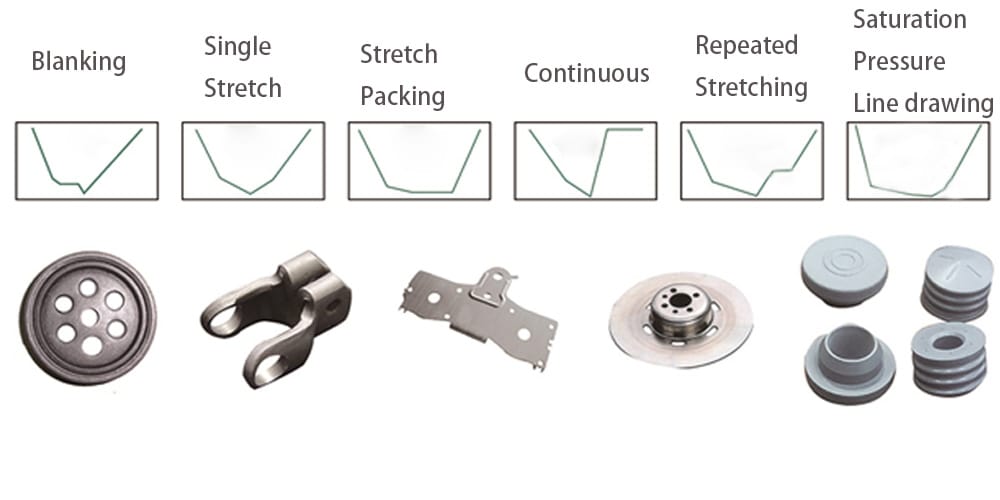

✅ Programmable multi-stage stamping curves for complex forming processes.

Click here to read our detailed comparison blog and discover which press is the best fit for your production needs!

No! Our design significantly reduces maintenance needs:

Yes! The body is processed with CNC laser cutting + CO₂ welding, paired with precision gears (ground by gear grinding machines), achieving a maximum continuous speed, suitable for high-precision applications like electronic components.

Fill out the form below, and we will be in touch shortly.