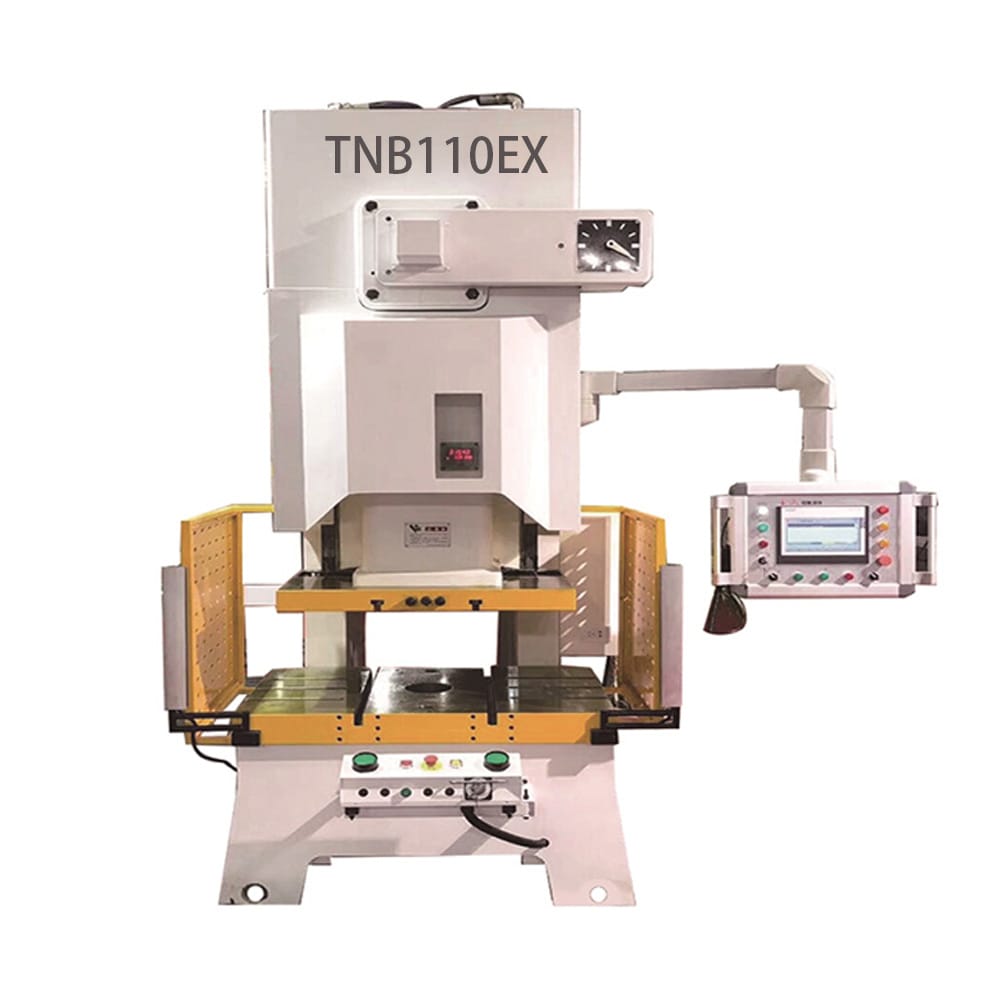

Standard Configuration

- Hydraulic Overload Protection Device

- Dry Combination Clutch/Brake System

- Slide and Die Balancing System

- Variable Frequency Speed Control

- Main Motor Reversing Device

- Adjustment & Measurement

- Manual Slide Adjustment (for ≤TP60-ton models)

- Electric Slide Adjustment (for ≥TP80-ton models)

- Mechanical Die Height Indicator (for ≤TP60-ton models)

- Digital Die Height Indicator (for ≥TP80-ton models)

- Crankshaft Angle Indicator

- Rotary Encoder

- Safety & Control

- Dual Solenoid Valves (International Brands)

- Photoelectric Safety Guard (Light Curtain)

- Misfeed Detection Interface

- Double-Stroke Prevention Device

- Operation & Display

- Touchscreen Control Panel (Pre-cut/Preload/Total Count)

- Production Counter

- LED Die Lighting

- Auxiliary Systems

- Air Source Connection (Standard Pneumatic Interface)

- Air Blow-off System (Debris Removal)

- Automatic Grease Lubrication System

- Anti-Vibration Mounts

- Maintenance & Accessories

- Maintenance Tool Kit (with Toolbox)

- User Manual

- Manual Oil Port for Balance Cylinder

Optional Configurations

- Power & Transmission Upgrades

- Wet Clutch (for high-frequency stamping)

- Pneumatic Cushion System (for deep drawing)

- Automation & Efficiency Enhancement

- Quick Die Change System (Lifters/Clamps/Shuttle Tables)

- Feeders (Pneumatic/Mechanical/NC Servo)

- Leveling Machine (Material Straightening)

- Industrial Robot (Automatic Loading/Unloading)

- Material Rack (Coil/Sheet Support)

- Operation & Safety Extensions

- Foot Pedal Switch (Single/Dual Control)

- T-Shaped Control Panel (Multi-Station Operation)

- Upper Knockout Device (Ejector Mechanism)

- Specialized Process Adaptations

- Hydraulic-Pneumatic Cushion Kit (Complex Forming Support)