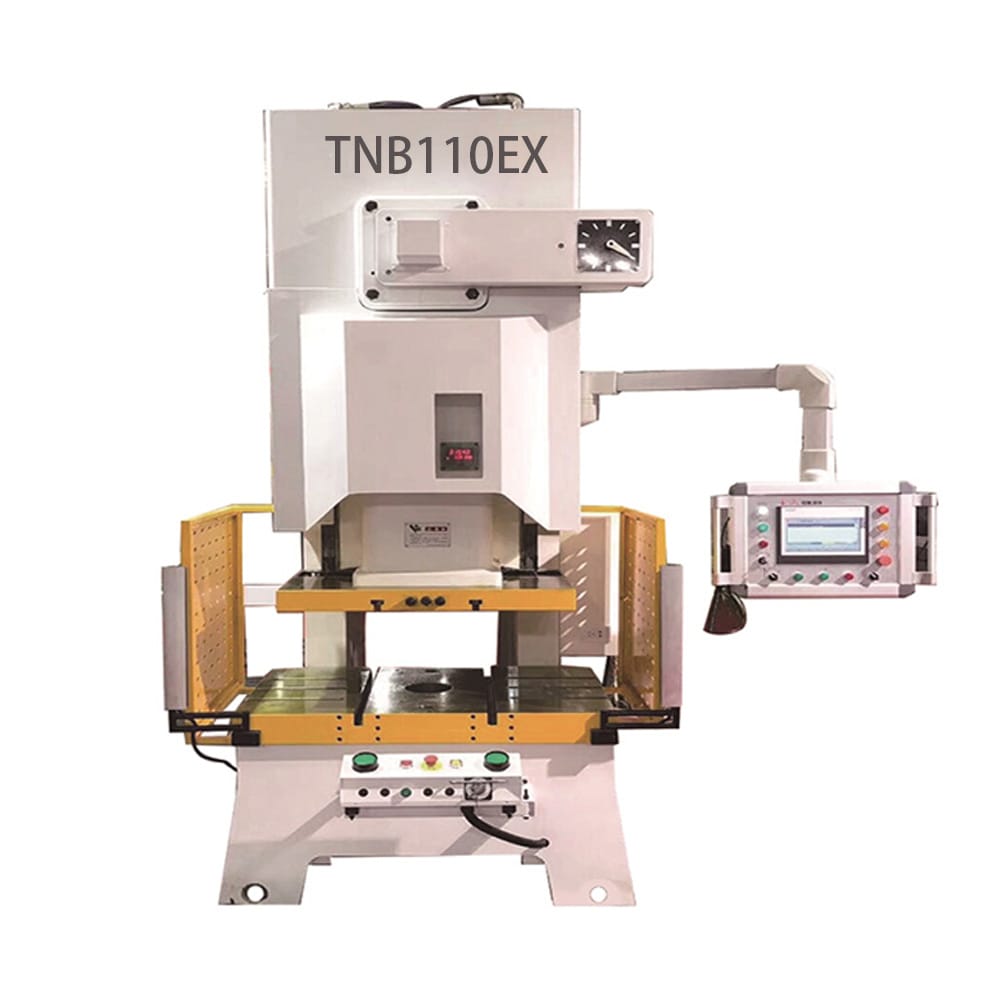

Standard Configuration

- Hydraulic Overload Protector

- Variable Frequency Drive (VFD)

- Digital Die Height Indicator

- Slide and Die Balancing Device

- Electronic Cam Switch Unit

- Preset Cycle Counter

- Air Source Quick-Connect Coupling

- Double Stroke Prevention System

- Air Blow-off System

- Stand-Alone Control Panel

- Misfeed Detection Sensor

- Main Motor Reversing Mechanism

- Photoelectric Safety Light Curtain

- Imported Oil-Mist Collector with Silencer

- Centralized Thin-Oil Lubrication Unit

- Industrial Power Receptacle

- Touchscreen HMI (Pre-cut/Preset/Totalizer)

- LED Die Area Illumination

- T-Style Operator Control Station

Optional Configurations

- Pneumatic Die Cushion System

- Quick Die Change System (Lifter/Clamp/Transfer)

- Material Feeders (Pneumatic/Mechanical/CNC)

- Coil Reel/Uncoiler Assembly

- Precision Material Leveler

- Robotic Material Handling Arm