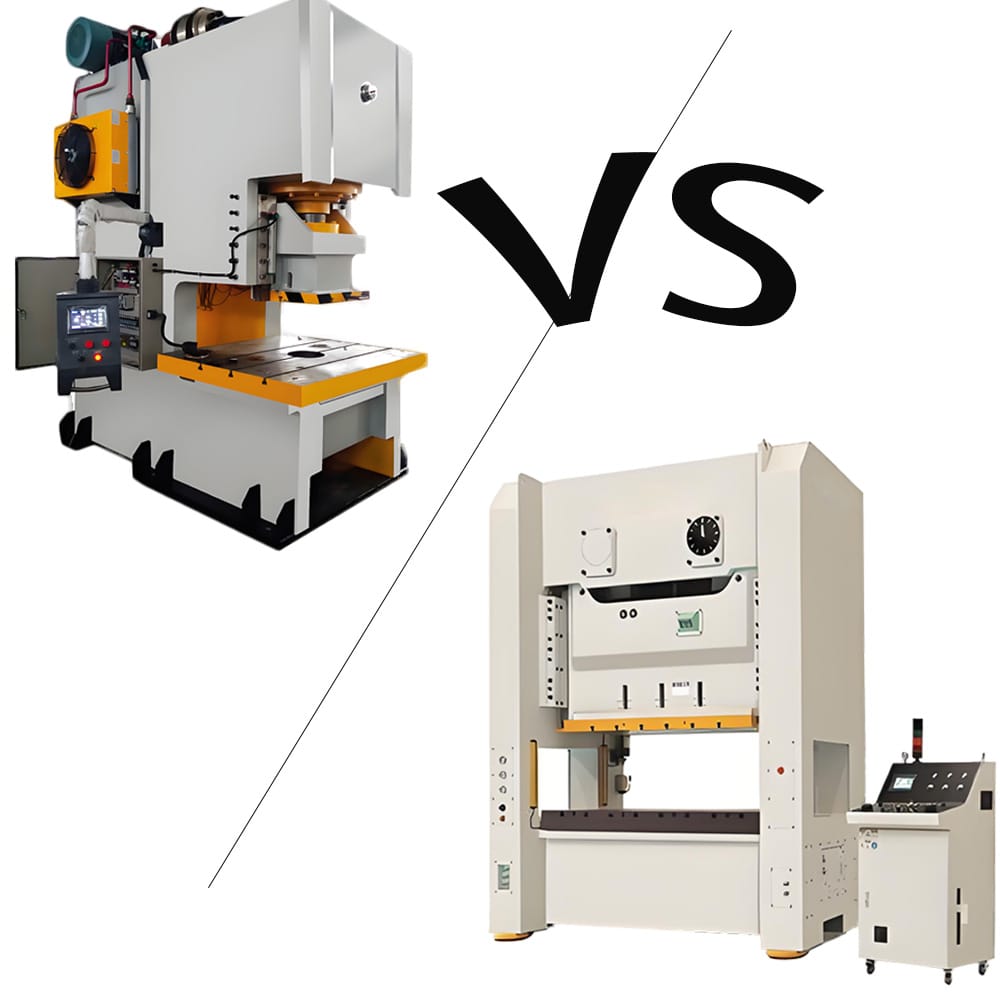

Two popular options are servo-electric presses and hydraulic presses. Each has unique strengths, but which one fits your production? Let’s break it down simply.

A hydraulic press uses fluid and pumps to create a powerful force. It moves a cylinder to bend or shape materials. It’s great for heavy tasks like making car or airplane parts.

A servo press runs on electric motors with smart controls. It adjusts speed and position with high accuracy. This makes it perfect for delicate jobs, like building medical devices or electronics.

Saves Energy: Uses power only when working, cutting energy costs by up to 60%.

Super Accurate: Delivers precise results for consistent quality.

Low Maintenance: No fluids or valves mean less upkeep.

Flexible: Easily adjusts for different tasks.

Powerful: Handles thick metals and heavy jobs with ease.

Tough: Built to last in rough factory settings.

Cheaper Upfront: Costs less to buy than servo presses.

Automotive: Perfect for precise tasks like assembling gears.

Medical Devices: Makes tiny, accurate parts safely.

Electronics: Handles fast, repeatable jobs.

Aerospace: Shapes large metal parts effortlessly.

Stamping: Powers high-volume production.

Repairs: Fixes or bends heavy machinery.

Servo presses cost more upfront but saves money over time. They use less power and need little maintenance. Hydraulic presses are cheaper to buy but require regular fluid changes and repairs due to leaks.

Ask yourself:

What’s Your Priority? Need precision or raw strength?

What’s Your Budget? Can you invest more now to save later?

Your Factory Setup? Prefer a clean, quiet servo or a rugged hydraulic?

Servo presses are ideal for precise, high-tech manufacturing. Some servo punch presses can also perform heavy-duty, high-intensity operations. e.g.TNC-TD/FD Series 400~4000TONS Hydraulic presses are best for heavy, high-force jobs. You’ll improve productivity and cut costs by matching the press to your needs.

👉 [Click here for a free consultation] with an engineer!

Fill out the form below, and we will be in touch shortly.