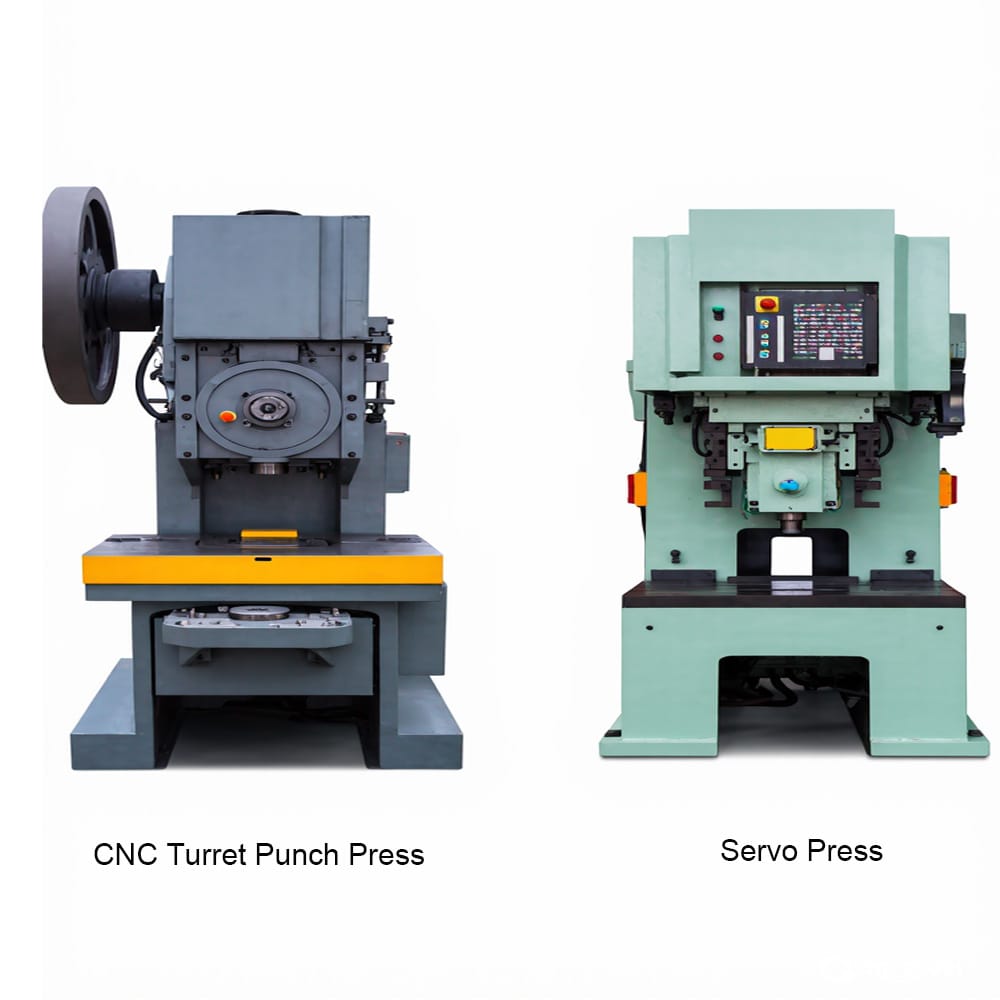

If you’re debating whether a CNC punch press (especially a turret punch press) or a modern servo press is ideal for your operations, you’re not alone. While both machines handle metal forming, their core technologies, capabilities, and applications differ fundamentally. This guide breaks down these differences to help you invest wisely.

Drive System: Traditional CNC punch press machines use mechanical flywheel/crank mechanisms or hydraulic systems. Energy stored in a rotating flywheel is released via a clutch to drive the ram in a fixed vertical motion.

Motion Control: Limited flexibility – ram speed and force curves are mechanically predetermined. CNC control focuses on X/Y table positioning and automatic tool selection (in turret punch press models via a rotating turret with 20–60+ tools).

Key Advantage: Unmatched efficiency for high-volume hole punching, cutting, and shallow forming across large sheets.

Drive System: A servo motor replaces flywheels/clutches, driving the ram directly via ballscrews or linkages.

Motion Control: Game-changing flexibility! Ram motion is fully programmable – control speed, dwell time, and position at any stroke point. Optimize curves for deep drawing, coining, or rapid cycling.

Key Advantage: Unlocks complex, precision-dependent processes like deep drawing and fine blanking with superior accuracy.

Rapid hole punching (round, square, custom shapes), nibbling, louvering, and shallow forming (dimples, embossing).

High-mix, low-volume production – the rotating turret enables instant tool changes, perfect for sheet metal fabrication (e.g., enclosures, panels, chassis).

Demanding forming processes needing precise control:

Deep drawing (automotive parts, sinks)

Fine blanking (ultra-smooth edges)

Precision coining/stamping

Complex bending (controlled springback)

Assembly (bearing pressing, riveting).

Ideal for high-strength materials, critical tolerances, and process optimization.

Feature | CNC Turret Punch Press | Servo Press |

|---|---|---|

Drive System |

Flywheel/Hydraulic |

Servo Motor |

Ram Motion |

Fixed curve (vertical) |

Fully programmable |

Key Strength |

High-speed punching, multi-tool flexibility, lower upfront cost |

Complex forming, superior accuracy, energy efficiency |

Best For |

Holes, cutouts, shallow forms |

Deep drawing, fine blanking, precision bends |

Energy Use |

Higher idle consumption |

Energy-on-demand (up to 60% savings) |

Noise/Vibration |

Moderate-High (mechanical impact) |

Low (no clutch engagement) |

Your focus is high-speed hole punching, sheet metal cutting, or light forming.

You process diverse part designs needing quick tool changes (turret advantage).

Budget is constrained, and punching efficiency is the priority.

You perform deep draws, precision stamping, or critical tolerance forming.

Material is high-strength steel/aluminum or requires optimized forming curves.

You prioritize energy savings, low noise, or Industry 4.0 integration.

CNC turret punch presses and servo presses aren’t rivals – they solve different problems. Smart manufacturers use them together:

A servo press forms complex parts (e.g., automotive brackets).

A CNC turret punch press adds holes, vents, or cutouts rapidly.

Understanding where CNC turret punching machines dominate (high-speed hole making) and where servo presses revolutionize (precision forming) is key to maximizing your ROI.

Fill out the form below, and we will be in touch shortly.