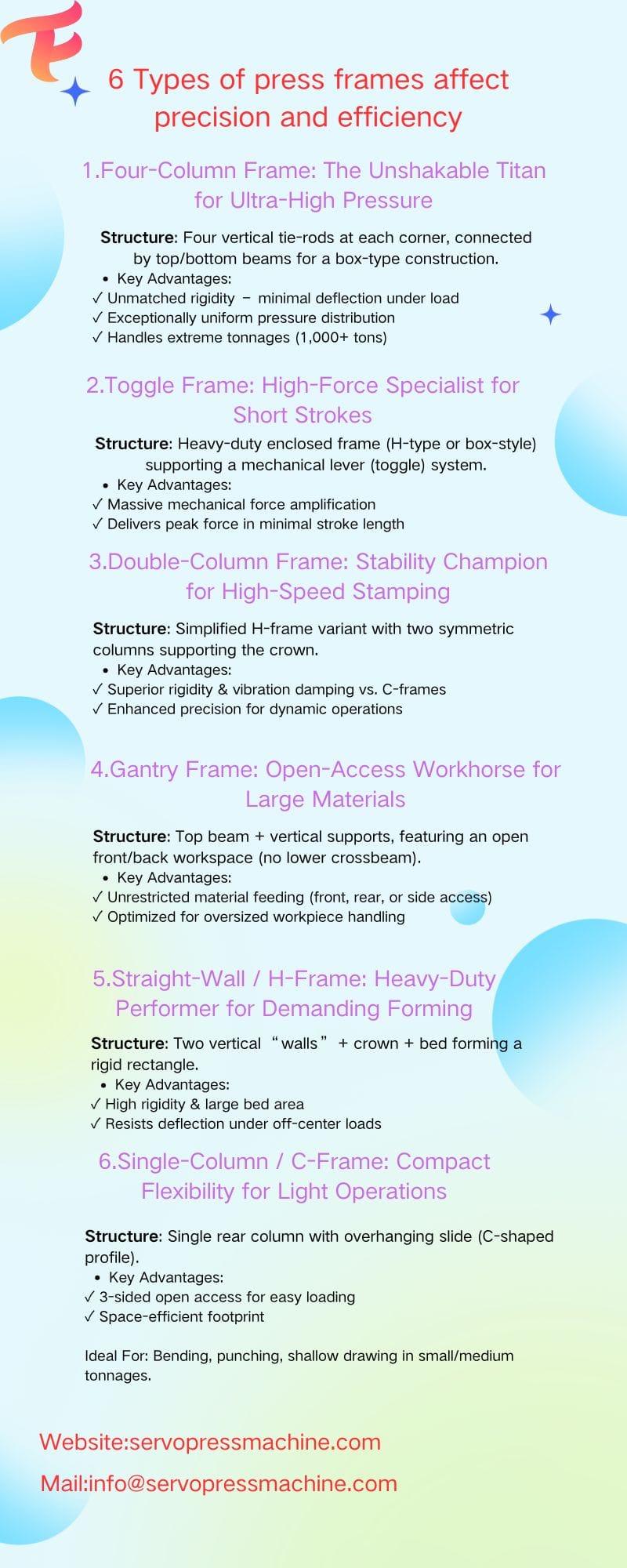

Understanding common frame types is critical for optimal performance. We break down Straight-Wall (H-Frame), Gantry, Single-Column (C-Frame), Double-Column, Four-Column, and Toggle press frames to guide your selection.

Structure: Four vertical tie-rods at each corner, connected by top/bottom beams for a box-type construction.

Key Advantages:

✓ Unmatched rigidity – minimal deflection under load

✓ Exceptionally uniform pressure distribution

✓ Handles extreme tonnages (1,000+ tons)

Ideal For: Heavy-duty forging, powder metallurgy compaction, lamination, rubber/plastic molding.

Our Solution: Our newly launched hydraulic press leverages this robust design for ultra-high-pressure applications, such as powder forming and precision forging. If you would like to customize hydraulic presses, please don’t hesitate to contact us.

Structure: Heavy-duty enclosed frame (H-type or box-style) supporting a mechanical lever (toggle) system.

Key Advantages:

✓ Massive mechanical force amplification

✓ Delivers peak force in minimal stroke length

Ideal For: Riveting, coining, embossing, precision stamping, powdered material compaction.

Our Solution: TNB-WO Series (5-500 Tons) excels in high-force, short-stroke operations like coining and riveting.

Structure: Simplified H-frame variant with two symmetric columns supporting the crown.

Key Advantages:

✓ Superior rigidity & vibration damping vs. C-frames

✓ Enhanced precision for dynamic operations

Ideal For: Medium-tonnage precision stamping, high-speed progressive dies.

Structure: Top beam + vertical supports, featuring an open front/back workspace (no lower crossbeam).

Key Advantages:

✓ Unrestricted material feeding (front, rear, or side access)

✓ Optimized for oversized workpiece handling

Ideal For: Large-sheet metal stamping, punching-shearing combos, bulky part processing.

Structure: Two vertical “walls” + crown + bed forming a rigid rectangle.

Key Advantages:

✓ High rigidity & large bed area

✓ Resists deflection under off-center loads

Ideal For: Automotive body panels, deep drawing, precision blanking.

Structure: Single rear column with overhanging slide (C-shaped profile).

Key Advantages:

✓ 3-sided open access for easy loading

✓ Space-efficient footprint

Ideal For: Bending, punching, shallow drawing in small/medium tonnages.

C-frame presses and H-frame presses are the most common types. If you want to learn more about the difference between the two, you are welcome to read this article. C Frame Press vs H Frame Press

Fill out the form below, and we will be in touch shortly.