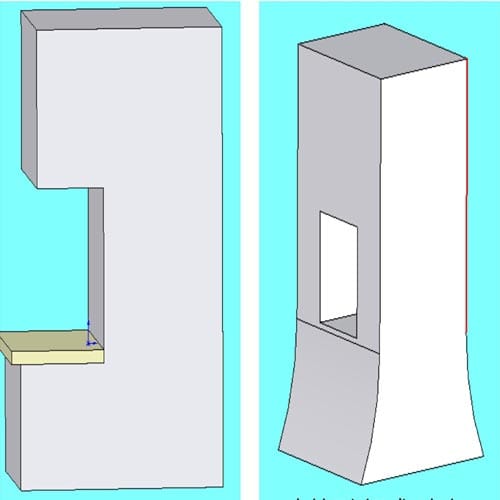

A C-Frame press, also commonly known as an open-frame press, features three open sides (front, left, and right), with only the rear support column. This open design allows for easy operator access to the die, manual loading and unloading, or integration of automated feeders (especially for coil feeds). eg our NB-EX series, TP-EX Series, TP-RX Series, this is our best-selling model.

The H-Frame press is often referred to as a closed-type press, but the more accurate and mainstream term is a “vertical-wall press” or “gantry press.” While it’s open front and back (facilitating the loading and unloading of large sheets), its left and right sides are completely enclosed by thick, vertical steel plates (vertical walls), forming a rigid “frame” or “gate” structure. Compared to the “open” nature of the C-frame, the enclosed nature of the H-frame’s sides is key to its high rigidity. Therefore, from the perspective of structural enclosure, it is sometimes informally referred to as a “closed-type” press, as opposed to the “open” C-frame.

Aspect | C Frame Press | H Frame Press |

|---|---|---|

Core Structure |

Single-column gap frame |

Dual-wall straight side press |

Deflection |

Up to 0.5mm (tonnage-dependent) |

<0.01mm/m (even at 2,000+ tons) |

C Frame Press Machine:

✅ 270° open access for robotics or manual loading.

H Frame Press:

❌ Front/rear access only (optimized for conveyor systems).

C-Frame: Compact (saves 40% floor space).

H-Frame: Requires reinforced foundations + crane access.

Slider Stability:

C Frame: Asymmetric forces cause tilt (e.g., ±0.1mm error in thin-blanking).

H Frame: Four-corner guided slides maintain <0.01mm/m vertical accuracy.

Off-Center Load Capacity:

C Frame: Fails at >15% offset (causes burrs in electronics stamping).

H Frame: Handles 30%+ offset (e.g., asymmetric auto frame forming).

Real-World Case: Automotive door panels require H Frame presses – C-frame deflection causes inconsistent panel gaps.

C Frame: Moderate vibration (85 dB) – needs isolators.

H Frame: Dampened vibration (75 dB) – suitable for factory floors.

C Frame: 10-15% lower energy use (servo-driven systems).

H Frame: Regenerative hydraulics cut energy waste by 25%.

Core Strengths: Fast setup, modular automation.

Industries:

Electronics: PCB stamping (≤100T)

Medical: Surgical tool forming

Jewelry: Hot press for C frame (200°C embossing)

Prototyping: Low-volume runs

Core Strengths: Zero-deflection under load.

Industries:

Automotive: Chassis forging (1,500T+)

Aerospace: Titanium rib forming

Energy: Pipeline flange machining

Defense: Armor plate pressing

Pros:

Cons:

Pros:

Cons:

<200T: C Frame press

>500T: Straight side press

Space-limited factories: Gap frame press

Thin coils (0.2-3mm) -C Frame Press Machine

Thick plate (20mm+) -H Frame press

C Frame: Easily integrates with robots.

H Frame: Built for tandem press lines.

For high-mix, low-volume flexibility, the C Frame press delivers unbeatable ROI. For heavy-section stamping with micron-level accuracy, the H Frame press is non-negotiable.

Fill out the form below, and we will be in touch shortly.