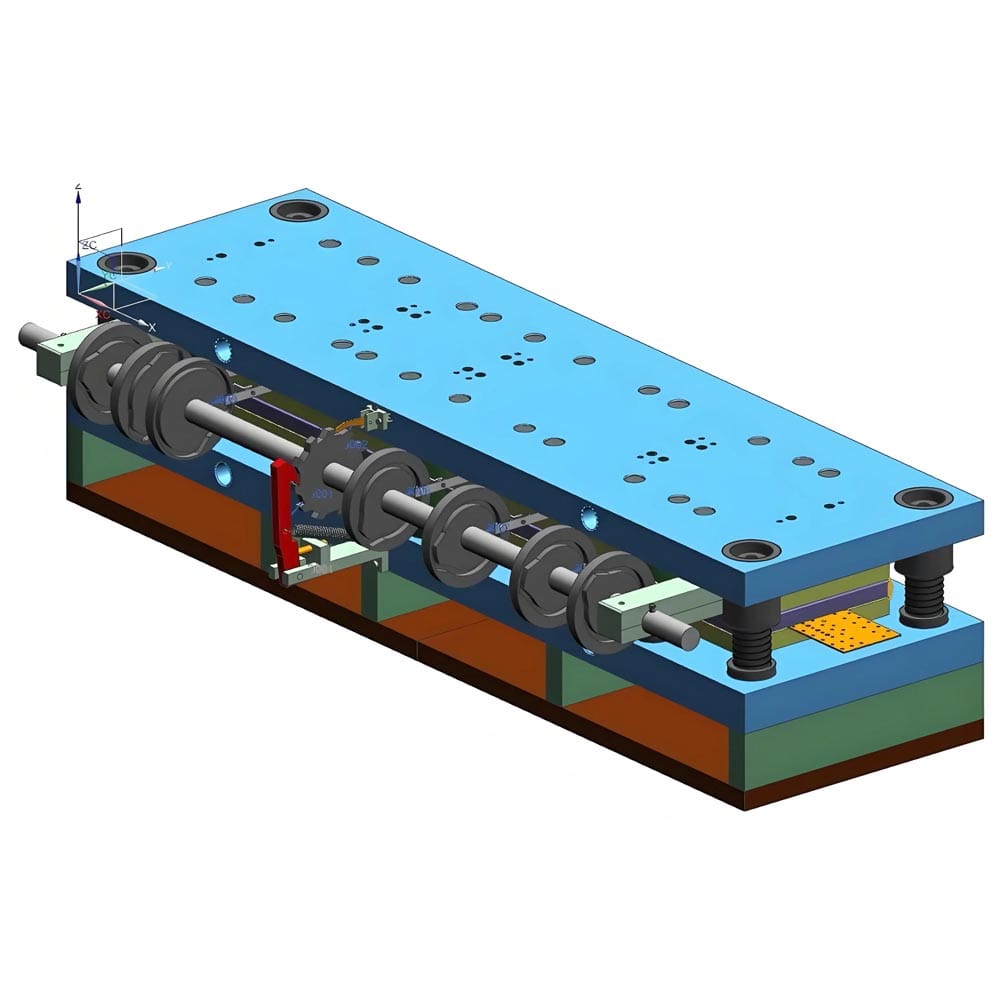

A progressive die press is a specialized type of stamping press designed to work with progressive dies and an automatic feeding system. Unlike a single-stage press that completes only one operation at a time, a progressive die press performs multiple operations—such as cutting, punching, bending, or forming—in a single press stroke, moving the material forward step by step through different stations.

Larger and more complex structure: Typically built with a closed-frame design to ensure strength and stability. The press body is longer than standard presses to accommodate multi-station dies and feeding equipment. (If you’re interested in learning more about press frame types, see our comparison of C Frame Press vs H Frame Press.)

Automatic feeding system: Always equipped with a continuous coil feeding system, including components like a decoiler (coil rack), straightener, and roller or pneumatic feeder. This system ensures smooth material transfer through each die station.

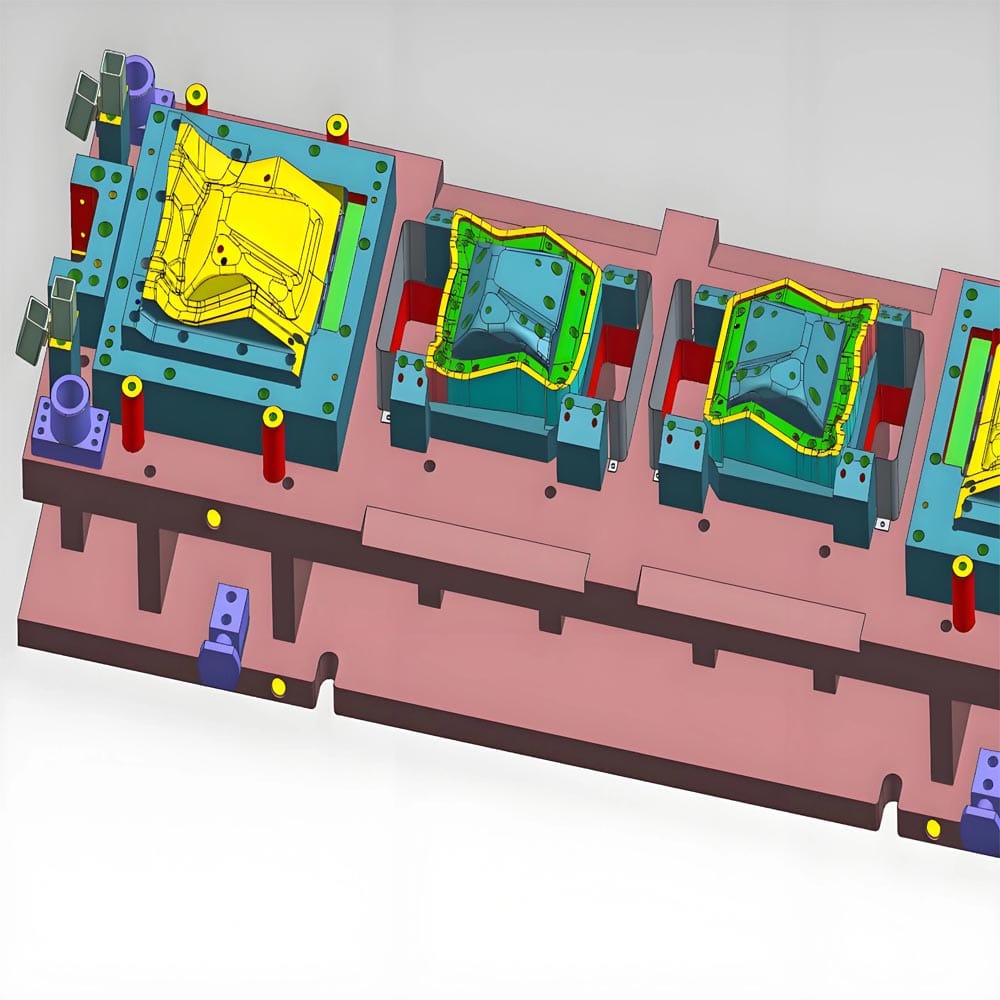

Multi-station progressive die: The die itself is longer, with several sequential workstations integrated into a single tool. Each stroke advances the sheet metal strip to the next station until the finished part is formed and separated.

Extended machine layout: Coil stock is usually fed from one side, passes through guiding rails or rollers, and exits after the metal stamping sequence. This creates a more “elongated” overall machine footprint.

Advanced control panel: Equipped with functions for feed speed adjustment, synchronization of multiple stations, error detection, and, in many modern presses, a touchscreen interface.

Safety measures: Due to their high-speed and continuous operation, progressive die presses are often equipped with protective barriers and safety sensors.

High productivity and efficiency: Multiple processes are completed in one stroke.

Reduced labor costs: Minimal operator intervention after setup.

Excellent consistency: Ensures uniform quality across large production runs.

Best suited for mass production: Common in industries such as automotive, home appliances, and consumer electronics.

When even greater precision or energy efficiency is required, manufacturers may consider servo stamping presses, which allow programmable stroke profiles and lower energy consumption compared to traditional mechanical presses.

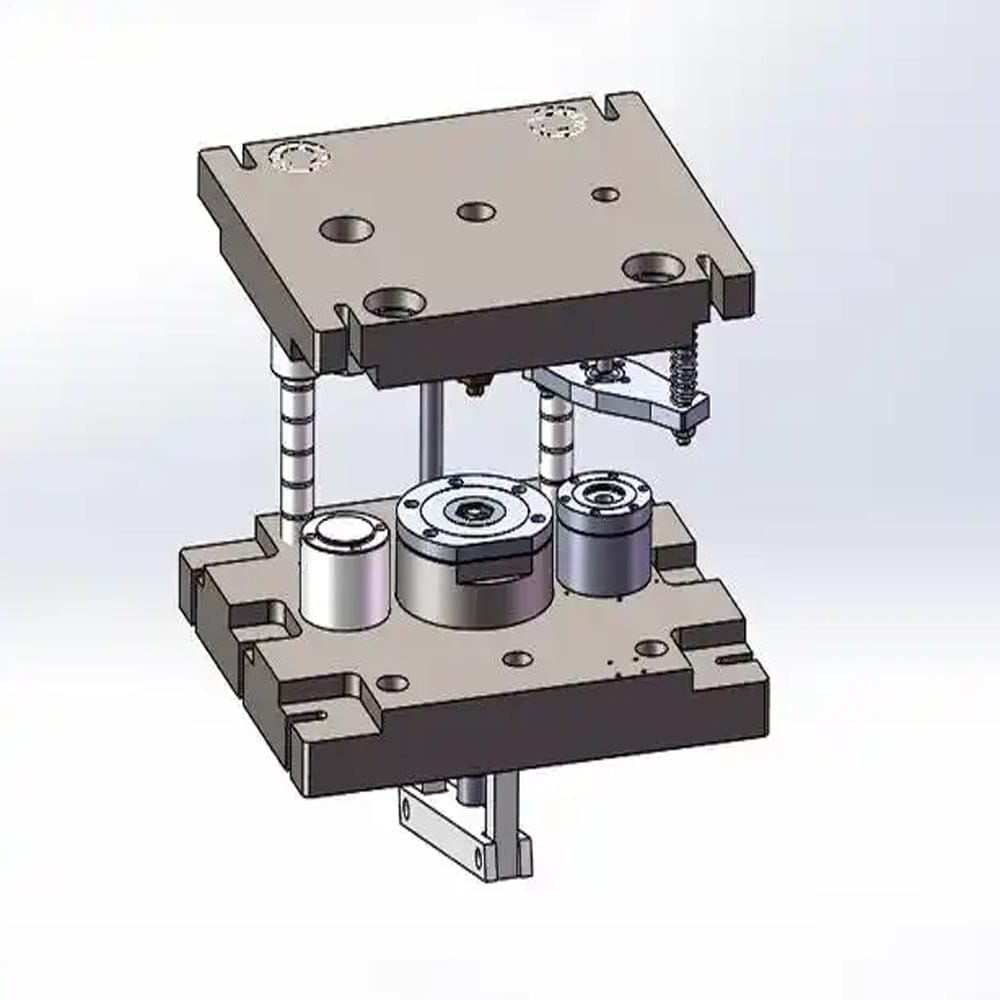

A single-stage press is a stamping press that performs only one operation per stroke. To produce a complete part, the operator must either replace the die or process the workpiece through multiple setups. It can also be equipped with a compound die. A compound die is designed to carry out two or more operations in a single stroke—for example, blanking and piercing simultaneously.

This setup enables manufacturers to maintain the simplicity and low cost of a single-stage press while improving efficiency for parts that require multiple operations.

Compact and simple design: Single-stage presses are usually smaller and less complex than progressive presses. The frame is often a C-frame or closed-frame, with a moderate worktable size. Since the press only handles one process at a time, it does not require feeding systems or multi-station tooling, making the machine’s outline more straightforward.

Basic appearance: A typical example is a small open-type single-stage press, where the structure looks like a sturdy “iron frame.” The power mechanism is mounted on the top, while a single worktable sits below, providing a clear and direct operating area.

No automatic feeding system: The worktable generally holds only one die set. Without continuous feeding or transfer mechanisms, the area around the die is more open and uncluttered. Operators must manually load and remove workpieces (or use simple robotic arms).

Simplified control panel: Controls usually include only basic functions such as start/stop and stroke adjustment. The machine is designed for manual single operations or simple automation.

High flexibility: Easy to adapt to different parts and quick changes.

Lower tooling cost: Dies are much cheaper than progressive dies.

Ideal for prototyping and precision work: Perfect for R&D, trial production, and small-lot custom jobs.

Compact footprint: Takes up less floor space compared to larger stamping presses.

Higher efficiency – Reduces the number of setups by combining operations.

Consistent accuracy – Ensures precise alignment between related processes such as piercing and blanking.

Cost-effective – More affordable than investing in progressive dies, while still saving labor and time.

Good for medium-volume production – Balances between flexibility and productivity.

Single-stage presses are best suited for:

Custom metal parts

Small batch orders

Prototyping and research environments

| Feature / Aspect | Progressive Die Press | Single Stage Press |

|---|---|---|

| Operation per Stroke | Multiple operations in sequence (cutting, punching, bending, forming) | Only one operation per stroke |

| Die Type | Progressive die (multi-station integrated tool) | Single die for one process |

| Feeding System | Equipped with an automatic coil feeding system (decoiler, straightener, feeder) | No continuous feeding; manual or semi-automatic loading |

| Machine Structure | Larger, closed-frame, elongated to fit multi-station tooling and feeding devices | Compact, simpler design; often C-frame or small closed-frame |

| Control Panel | Advanced (feed speed, synchronization, error detection, touchscreen) | Basic (start/stop, stroke adjustment) |

| Automation Level | High – designed for continuous operation | Low – relies on manual or simple automation |

| Productivity | Very high, best for mass production | Lower, best for small batches |

| Tooling Cost | Higher, due to complex progressive die | Lower, simple single dies |

| Applications | Automotive stamping, appliances, consumer electronics | Custom metal parts, R&D, prototyping, small-lot jobs |

| Typical Drive Systems | Can be powered by a servo press, pneumatic press, or hydraulic press, depending on application | Often available as pneumatic presses for light work, servo presses for precision, or hydraulic presses for heavy-duty tasks |

A progressive die press operates with a coil-fed automatic system. Sheet metal in coil form is unrolled, straightened, and fed continuously into the press. The strip advances step by step through a progressive die, which integrates multiple stations in one tool. With each press stroke, the material moves forward to the next station, where operations such as blanking, punching, bending, or forming are performed. Finally, the finished part is separated from the strip. This makes the process highly automated, efficient, and consistent for mass production.

A single stage press, by contrast, performs only one operation per stroke. The operator (or a simple handling device) places the workpiece on the press table, aligns it with the die, and activates the press. After the stroke, the part is removed manually and then either finished or moved to another die for further processing. Since each stage of production requires a separate setup, this process is more labor-intensive and time-consuming, but highly flexible for small batches, custom parts, and prototyping.

Both progressive die presses and single stage presses play important roles in metal stamping, but their applications differ significantly:

Use a progressive die press if you need high-volume production, excellent repeatability, and low cost per part.

Choose a single-stage press if you require flexibility, lower tooling costs, or prototyping capabilities.

In addition to selecting between progressive and single-stage processes, it is also important to consider the drive system of your press machine. Options such as a servo press, pneumatic press, or hydraulic press can further optimize performance depending on precision, speed, and force requirements.

👉 Contact our team today to learn which press and drive system is best for your production needs.

Q1: What is the main difference between a progressive die press and a single-stage press?

A progressive die press performs multiple operations in a single stroke using an automatic feeding system, while a single-stage press completes only one operation per stroke and usually requires manual handling.

Q2: Which press is better for prototyping?

A single-stage press is generally preferred for prototyping and R&D because of its flexibility and lower tooling cost.

Q3: Is a progressive die press more expensive than a single-stage press?

Yes, progressive die presses require a higher initial investment due to complex dies and automation systems. However, they reduce the cost per part in large-scale production.

Q4: Can both types of presses use servo, pneumatic, or hydraulic drive systems?

Yes. Both progressive and single-stage presses can be powered by servo, pneumatic, or hydraulic systems, depending on the application. For example, servo presses offer precision, pneumatic presses suit light-duty tasks, and hydraulic presses provide high tonnage capacity.

Q5: Which industries commonly use progressive die presses?

Progressive die presses are widely used in automotive manufacturing, appliance production, and consumer electronics, where large volumes of identical parts are needed.

Fill out the form below, and we will be in touch shortly.