Customize Your TNC-EO Electric ServoPress: 200Tons | 250Tons | 300Tons | 400Tons | 500Tons | 600Tons | 800Tons | 1000Tons | 1250Tons | 1600Tons |2000Tons

JIS Grade 1 certified, ideal for micro-stamping in aerospace, automotive, and electronics.

Robust closed-frame design minimizes deformation (<0.02mm), even under full 2000-ton load.

Servo motor eliminates flywheel idling, saving $25,000+ annually (300 operating days).

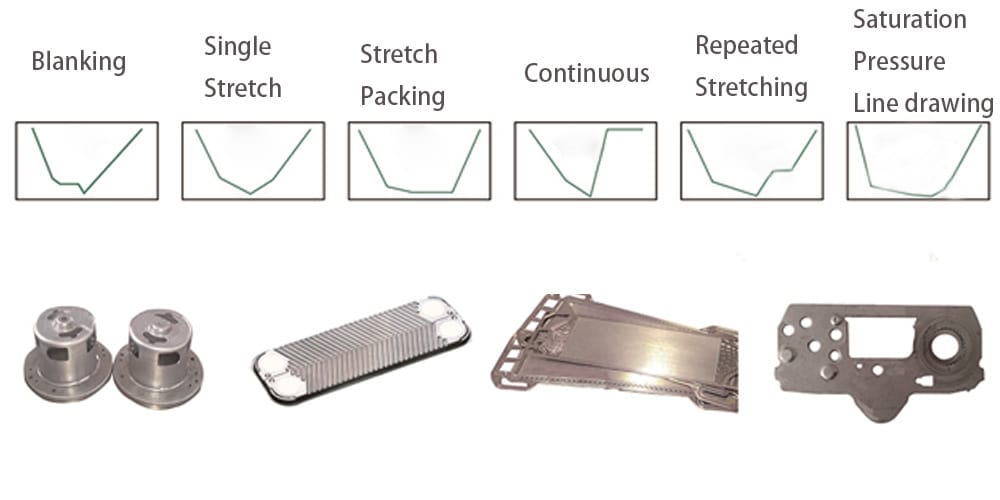

Stepless speed control (2-55 SPM) and programmable curves (blanks, stretches, dwells).

Engine components, sensor housings (±0.02mm).

Turbine blades, structural brackets (high-tolerance forming).

Shielding cases, connector pins (200 SPM speed).

EV battery shells, deep-drawn aluminum parts (with die cushion).

Model | TN200EO | TNC300EO | TNC400EO | TNC600EO | TNC800EO | TNC1000EO | TNC1250EO | TNC1600EO | TNC2000EO |

|---|---|---|---|---|---|---|---|---|---|

Nominal Force (kN) |

2000 |

3000 |

4000 |

6000 |

8000 |

10000 |

12500 |

16000 |

20000 |

Slide Stroke (mm) |

200 |

200 |

200 |

250 |

250 |

250 |

250 |

280 |

280 |

Continuous Stroke |

2-55 |

2-50 |

2-50 |

2-40 |

2-40 |

2-30 |

2-30 |

2-25 |

2-25 |

Single Strokes Per Minute (SPM) |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

Inching Strokes |

any |

any |

any |

any |

any |

any |

any |

any |

any |

Maximum Die Height (mm) |

450 |

500 |

500 |

700 |

700 |

750 |

750 |

800 |

800 |

Die Height Adjustment (mm) |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

Upper Table Size (mm) |

1000*900 |

1000*900 |

1000*900 |

1400*1000 |

1400*1100 |

1400*1200 |

1450*1200 |

1500*1250 |

1500*1300 |

Lower Table Size (mm) |

1100*900 |

1200*1000 |

1200*1000 |

1600*1100 |

1600*1200 |

1600*1200 |

1650*1250 |

1700*1300 |

1700*1350 |

Side Opening |

600*500 |

650*550 |

650*550 |

700*600 |

700*600 |

800*700 |

900*700 |

1000*900 |

1200*1000 |

Slide Adjustment Method |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Structural style |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

guide pillar and bushing type |

Guideway type |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

four-corner eight-face guideway |

Air Pressure (MPa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

Press Accuracy |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

FAQS For the Servo Press Industry

Our TNC-EO Series Servo Press offers:

70% energy savings compared to conventional presses, thanks to servo motors that activate only during stamping.

JIS 1-grade precision (accuracy under 0.01 mm) for high-quality, repeatable results.

Low vibration and noise reduction, creating a quieter, safer workspace.

Maintenance-free design (no flywheel, belts, or clutch), reducing downtime and consumables.

Our precision servo presses excel in:

High-precision metal forming (e.g., automotive parts, electronics).

Stamping, blanking, and deep drawing with stretch packing and constant pressure.

Noise-sensitive environments like factories requiring OSHA compliance.

The pneumatic blow device and speedy connectors ensure:

Efficient material handling (e.g., rapid ejection of stamped parts).

Quick die changes with optional Quick Die Change (Q.D.C.) systems.

Reduced wear and tear through simplified, lightweight components.

Safety is prioritized with:

Photoelectric safety devices to prevent operator injuries.

Touchscreen controls for “visualized” production monitoring.

Error detection interfaces to halt operations during malfunctions.

Our energy-saving servo presses reduce power consumption by 70% versus traditional models. The servo motor operates only during active stamping, eliminating idle energy waste.

Minimal maintenance: No belts, flywheels, or clutches to replace.

Self-lubricating guides and rotary encoders ensure long-term reliability.

Optional automatic feeding systems further reduce manual intervention.

Yes! The TNC-EO Series offers:

Max mounting heights up to 800 mm (TNC2000E0 model).

Stepless speed regulation for flexible stroke adjustments.

Side openings up to 1200×1000 mm for oversized tooling.

All models meet JIS 1-grade precision standards and include CE-certified components for global safety and performance compliance.

Enhance productivity with:

Quick Die Change (Q.D.C.) for reduced setup time.

Automatic feeding devices (feeders, racks, straighteners).

Pneumatic die cushions for complex forming operations.

Review our technical parameters table for capacity (200–2000 tons), stroke length (200–280 mm), and platform sizes. Contact us for a free consultation based on your material type, precision needs, and production volume.

Fill out the form below, and we will be in touch shortly.