Customize Your TNC-RO Electric ServoPress: 110Tons | 160Tons | 200Tons | 300Tons | 400Tons | 500Tons | 600Tons | 800Tons | 1000Tons

JIS Grade 1 certification, ideal for micro-stamping in aerospace and automotive industries.

Servo motor operates only during stamping, reducing power consumption by 70% vs traditional presses.

A closed double-point design ensures stability and reduces deformation (<0.02mm) under 1000-ton loads.

No flywheel, belt, or clutch—minimal wear parts and maintenance costs.

Engine blocks, chassis components (±0.02mm precision).

Turbine blades, structural brackets (high-tolerance forming).

EV battery casings, deep-drawn aluminum parts (with die cushion).

Large-scale metal forming (low noise <65dB).

Model | TNC110RO | TNC160RO | TNC200RO | TNC300RO | TNC400RO | TNC500RO | TNC600RO | TNC800RO | TNC1000RO |

|---|---|---|---|---|---|---|---|---|---|

Nominal Force (kN) |

1100 |

1600 |

2000 |

3000 |

4000 |

5000 |

6000 |

8000 |

10000 |

Slide Stroke (mm) |

180 |

200 |

250 |

280 |

280 |

280 |

280 |

280 |

300 |

Continuous Stroke |

2-90 |

2-80 |

2-70 |

2-60 |

2-60 |

2-50 |

2-50 |

2-40 |

2-30 |

Single Strokes Per Minute (SPM) |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

Inching Strokes |

- |

- |

any |

any |

any |

any |

any |

any |

- |

Maximum Die Height (mm) |

400 |

460 |

500 |

550 |

550 |

550 |

550 |

600 |

700 |

Die Height Adjustment (mm) |

80 |

100 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

Upper Table Size (mm) |

1500*650 |

1600*650 |

1850*750 |

2100*900 |

2100*900 |

2900*1100 |

3000*1100 |

3000*1100 |

3000*1200 |

Lower Table Size (mm) |

1700*720 |

1800*760 |

2200*940 |

2400*1000 |

2400*1000 |

3100*1100 |

3200*1100 |

3200*1200 |

3300*1300 |

Side Opening |

700*400 |

700*500 |

800*500 |

900*600 |

900*600 |

1000*700 |

1000*700 |

1000*700 |

1100*700 |

Slide Adjustment Method |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Air Pressure (MPa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

Press Accuracy |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

FAQS For the Servo Press Industry

Servo presses use energy-efficient servo motors that only activate during stamping, reducing power consumption by 70% compared to traditional presses.

They eliminate flywheels, belts, and clutches, resulting in lower noise, vibration, and maintenance costs.

Precision control ensures accuracy up to 0.01 mm, meeting JIS Class 1 standards, ideal for high-precision applications.

The servo motor operates on-demand, avoiding constant energy use. Combined with stepless speed regulation and touchscreen controls, it optimizes power usage and reduces operational costs.

Yes! Our servo presses achieve significant noise reduction by eliminating mechanical components like flywheels. They are ideal for factories requiring quiet operations or complying with strict environmental regulations.

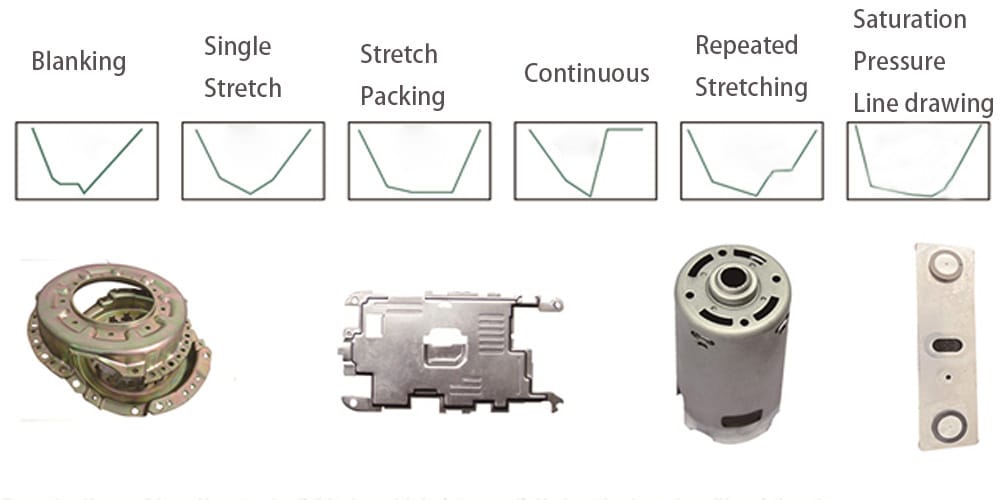

Absolutely. The TNC-RO series supports single stretch, stretch packing, and repeated stretching with customizable motion curves. The rotary encoder ensures precise control for complex tasks.

Select based on:

Capacity (1100–10,000 kN).

Stroke length (180–300 mm).

Platform size (up to 3300×1300 mm).

Contact our team for a tailored recommendation based on your production needs.

Yes! Optional configurations include quick die change devices, automatic feeders, and mechanism hands for seamless integration into automated production lines.

The maintenance-free design eliminates belts and clutches. Routine checks for the pneumatic system and touchscreen calibration are recommended.

Yes, it meets JIS Class 1 precision standards and includes certifications for safety, environmental protection, and energy efficiency.

The touchscreen interface enables real-time visualization of production metrics, simplifying quality management, OEE tracking, and workflow optimization.

Fill out the form below, and we will be in touch shortly.