A servo motor and drive controller enable the dynamic adjustment of bottom dead center (BDC) stamping curves.

Reinforced structure minimizes frame deformation

Ultra-low vibration design meets Japanese JIS Class 1 standards (±0.01mm repeatability).

Multi-layer human-machine protection (CE/UL compliant) with automation interfaces.

Electric lubrication + optimized power consumption reduces energy usage by 30% vs. conventional presses.

Customize Your NB-EX Electric ServoPress: 10Tons|15Tons|25Tons | 45Tons | 60Tons | 80Tons | 125Tons | 160Tons | 200Tons | 250Tons | 300Tons

Model | NB25EX | NB45EX | NB60EX | NB80EX | NB125EX | NB160EX | NB200EX | NB250EX | NB300EX |

|---|---|---|---|---|---|---|---|---|---|

Nominal Force (kN) |

250 |

450 |

600 |

800 |

1250 |

1600 |

2000 |

2500 |

3000 |

Slide Stroke (mm) |

70 |

80 |

120 |

150 |

180 |

200 |

200 |

200 |

250 |

Continuous Stroke |

2-180 |

2-150 |

2-135 |

2-120 |

2-90 |

2-70 |

2-65 |

2-60 |

2-40 |

Single Strokes Per Minute (SPM) |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

unlimited |

Inching Strokes |

any |

any |

any |

any |

any |

any |

any |

any |

any |

Maximum Die Height (mm) |

195 |

250 |

310 |

340 |

360 |

400 |

420 |

460 |

500 |

Die Height Adjustment (mm) |

50 |

60 |

75 |

80 |

80 |

100 |

100 |

110 |

120 |

Upper Table Size (mm) |

470*230*50 |

560*340*60 |

700*400*70 |

770*420*70 |

910*560*80 |

990*560*90 |

1050*600*90 |

1130*650*90 |

1200*700*100 |

Lower Table Size (mm) |

680*300*70 |

850*440*80 |

900*500*80 |

1000*550*90 |

1150*700*110 |

1250*760*140 |

1350*800*140 |

1400*820*150 |

1500*840*180 |

Distance from Slider Center to fuselage (mm) |

155 |

225 |

255 |

280 |

355 |

385 |

405 |

415 |

425 |

Shank Hole (mm) |

Φ40 |

Φ40 |

Φ50 |

Φ50 |

Φ50 |

Φ65 |

Φ65 |

Φ65 |

Φ65 |

Slide Adjustment Method |

manual adjustment |

manual adjustment |

manual adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Electric Adjustment |

Air Pressure (MPa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

Press Accuracy |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

JIS Class 1 |

Mold pad capacity(ton) |

—— |

2.3 |

3.6 |

3.6 |

6.3 |

10 |

10 |

14 |

14 |

Die pad stroke(mm) |

—— |

50 |

70 |

70 |

80 |

80 |

80 |

100 |

100 |

Effective area of mold pad(mm) |

—— |

250*230 |

300*300 |

400*310 |

450*350 |

600*420 |

600*420 |

620*480 |

700*480 |

We can also adjust the parameters according to your mold size. Don’t hesitate to get in touch with us for a customized servo punch press.

Optimizes punch speed through the material for clean cuts and extended tool life.

Precisely controls drawing speed and depth for wrinkle-free, single-stage draws.

Maintains specific pressure (dwell) at the bottom of the stroke for critical forming or coining operations.

Enables high-speed, successive stamping operations with smooth transitions between cycles.

Advantages: Eliminates complex surface springback, improves material yield, meets UHSS forming requirements.

► Deep drawing of hoods/doors ► Precision gear cold forging ► Airbag component stamping ► HSS body structure forming

Advantages: Burr-free cutting of ultra-thin materials (0.1mm±), multi-stage micro-part drawing, crack-free Mg/Al alloy heating forming.

► Smartphone metal frames ► Connector pins ► Heat sinks ► Micro-motor housings

Advantages: Controls strain rate & temperature for hard-to-form materials (Ti/Ni alloys), ensures part fatigue strength.

► Turbine blade precision forging ► Titanium pressure vessel hot forming ► Superalloy honeycomb structures

Advantages: High-efficiency curved surface production, complex texture coining, automated feeding integration.

► Stainless steel washer drums ► Refrigerator door panel embossing ► Oven multi-layer panels

Advantages: Zero surface contamination control, regulated biomaterial grain structure, meets implant micron-level precision.

► Surgical instrument housings ► Orthopedic implant encapsulation ► Biocompatible metal stents

Advantages: Micron-scale channel imprinting, prevents ultra-thin tube wrinkling, ensures high-pressure seal integrity.

► Fuel cell bipolar plate micro-channels ► Solar thermal collector ultra-thin tubing ► Nuclear seal precision forging

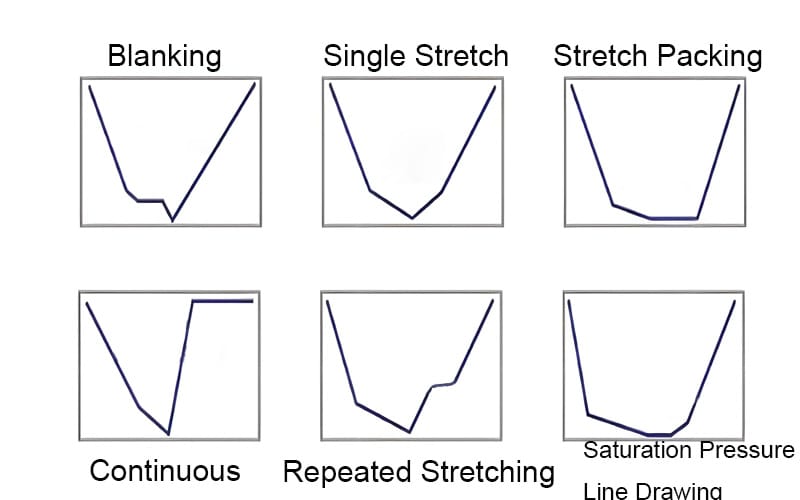

Press Blanking/Drawing Curve:

Feature: Slow, controlled forming speed – Ideal for clean cuts and deep draws requiring precise material flow.

Press Coining Curve:

Feature: Dwell at Bottom Dead Center (BDC) – Applies sustained pressure for precision coining, embossing, or sizing.

Feeder Synchronization Curve:

Feature: Optimized for feeder clamping & release – Ensures perfect material feed timing and grip coordination.

Pulse Forming Curve:

Feature: Repeated drawing motion – Enables complex, multi-stage draws (like progressive redrawing) within a single cycle.

In-Die Heating Curve:

Feature: Clamping the workpiece during heating – Facilitates warm/hot forming processes by holding the part within heated dies.

Drive System: Direct servo motor drive

Motion Control: Fully programmable position/speed curves

Energy Consumption: 70% less (Power-on-demand)

Forming Precision: ±0.01mm repeatability

Processing Flexibility: 20+ built-in curves (e.g. pulse forming)

Drive System: Compressed air cylinders

Motion Control: Fixed stroke cycle

Energy Consumption: Constant air compression required

Forming Precision: ±0.1mm typical tolerance

Processing Flexibility: Single operating mode

JIS Grade 1 certification, ideal for micro-stamping in electronics and medical industries.

Direct servo motor drive eliminates flywheel idling, saving over $15,000 annually (300 operating days).

Stepless speed control (2-180 SPM) and programmable stamping curves (6 modes: blanking, stretching, dwell, etc.).

High-rigidity frame design (deformation <0.02mm) supports continuous 300-ton stamping.

FAQS For the Servo Press Industry

NB-EX is optimized for small-to-medium batch production (e.g., electronics, household appliances) with a tonnage range of 25–300 tons. Its compact design and energy efficiency suit workshops with space or budget constraints.

Lower energy consumption and noise levels due to optimized servo motor control.

Simplified mold height adjustment and ergonomic controls reduce operator training time.

Standard stepless speed regulation allows flexible adaptation to diverse materials.

Yes, Automation tools (e.g., quick die change devices) are optional. The series focuses on core affordability while supporting basic add-ons like preset counters and knockout devices.

Absolutely. It meets Grade JIS 1 standards and offers practical electric lubrication as standard, ensuring smooth operation and consistent accuracy for small-part stamping.

A servo press (also called an electric servo press) is a high-precision stamping machine powered by a servo motor + control system. It directly drives the crankshaft or linkage mechanism without traditional components like flywheels, clutches, or brakes, enabling programmable control over stroke, speed, and force for energy-efficient and flexible operations.

Click here to read our detailed comparison blog and discover which press is the best fit for your production needs!

Feature | Servo Press | Hydraulic Press |

|---|---|---|

Precision |

±0.01mm (JIS Grade 1) |

±0.1mm (lower due to fluid compressibility) |

Speed |

High (up to 1200 SPM) |

Low to medium (typically 10-60 SPM) |

Energy Efficiency |

30~60% energy savings |

High energy consumption |

Flexibility |

Programmable stroke,speed,and force |

Limited motion control |

Maintenance |

Low (no hydraulic oil or seals) |

High (frequent oil and seal changes) |

Noise Level |

Quieter (10~15dB lower) |

Louder (pump and fluid noise) |

Our servo press adopts direct servo motor drive technology, offering the following advantages over traditional mechanical presses:

✅Energy savings of over 30% (no flywheel idling losses)

✅ Repeat positioning accuracy of ±0.01mm (certified to JIS Grade 1)

✅ Programmable multi-stage stamping curves for complex forming processes.

Click here to read our detailed comparison blog and discover which press is the best fit for your production needs!

No! Our design significantly reduces maintenance needs:

Yes! The body is processed with CNC laser cutting + CO₂ welding, paired with precision gears (ground by German gear grinding machines), achieving a maximum continuous speed, suitable for high-precision applications like electronic components.

Fill out the form below, and we will be in touch shortly.