Choose right, and you’ll get both efficiency and cost savings; choose wrong, and you’ll be stuck with poor precision and excessive energy consumption.

Today, we’ll break down the core differences between these two types of punch presses — after reading, you’ll know which one your workshop should go for.

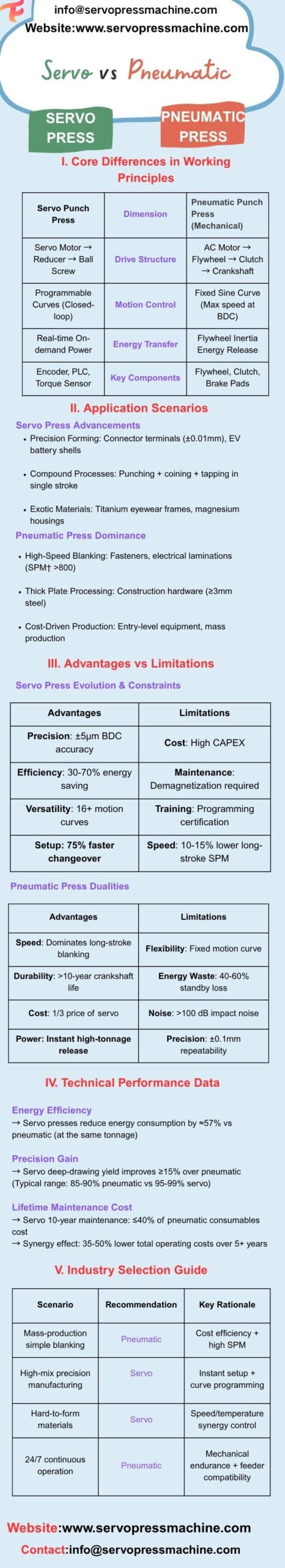

The pneumatic stamping press, also known as a pneumatic press or pneumatic punch press, is a workhorse in metal stamping. Its core design relies on an AC induction motor running at constant speed.

Energy Storage & Transfer: The motor continuously drives a heavy flywheel, storing kinetic energy. During operation, an air clutch engages, transferring the flywheel’s rotation to a crankshaft (or eccentric gear).

Motion Conversion: The crankshaft/eccentric gear converts rotary motion into the linear reciprocating movement of the ram/slider via a connecting rod mechanism.

Stopping: At the cycle’s end, a pneumatic air press brake stops the motion.

Fixed Cycle: Fixed stroke length and fixed speed curve (sinusoidal).

Inflexible Path: Ram trajectory, speed, and bottom dead center (BDC) position are essentially fixed (limited mechanical adjustment possible). Each stroke relies primarily on the flywheel’s stored inertial energy.

Fixed Curve: Movement follows a rigid sinusoidal curve – fastest near BDC, zero speed at top/bottom dead centers.

Fixed Stroke: Length determined mechanically (crank eccentricity), adjustments are limited and time-consuming.

Single Speed: Maximum Strokes Per Minute (SPM) is key, but speed variation within the stroke is uncontrollable.

Low Flexibility: Unsuitable for processes needing special motion profiles (e.g., deep drawing, coining, tapping, ironing).

Repeatability: Relies on mechanical tolerance (bearing play, linkage wear), typically around ±0.1mm. Accuracy degrades over time and at high speeds due to inertia.

BDC Stability: Significantly affected by flywheel inertia and load changes, leading to lower stability.

Control: Basic start/stop (via clutch/brake). Precise force/tonnage control requires separate hydraulic/pneumatic cushions and is limited.

High-Speed Advantage: Excels at high nominal SPM for long-stroke, simple blanking operations due to flywheel energy.

Real-World Efficiency: Cannot leverage speed for processes needing dwell time or slow forming; may even require reduced speed.

Changeover Time: Adjusting stroke or changing dies requires lengthy mechanical downtime.

Constant Energy Drain: The motor runs continuously to keep the flywheel spinning, consuming a significant amount of power even when idle (30%-70% of total energy, depending on utilization/flywheel size).

Air Consumption: Compressed air used for clutch/brake operation incurs an additional energy cost.

Noise & Vibration: High noise and vibration levels from flywheel, clutch engagement, and mechanical impact.

Impact Stress: Inherent high-speed impact increases stress on molds (especially precision/brittle types), accelerating wear and chipping.

Poor Flow Control: Fixed curve hinders optimization of material flow in complex forming (e.g., deep draw), increasing risks of cracking or wrinkling.

Lower Consistency: Reduced precision and stability affect part uniformity.

Complex Design: Numerous moving parts: motor, flywheel, clutch, brake, crankshaft/eccentric gear, linkages.

High Maintenance: Frequent checks, adjustments, and replacement needed for wear parts: clutch/brake linings, bearings, drive keys, and lubrication systems.

Higher Maintenance Cost: Accumulated costs from spare parts (linings) and labor are significant.

Low Initial Cost: Mature technology, relatively “simple” construction, lower manufacturing cost. Purchase price is typically much lower than equivalent tonnage servo presses.

Higher TCO: Significant energy consumption, elevated maintenance costs (parts, labor), potentially shorter mold life, and lower yield rates often result in a much higher long-term TCO.

High-volume, simple blanking (e.g., standard parts, electrical steel laminations).

Applications with low precision or forming complexity requirements.

Budget-conscious buyers are less sensitive to long-term energy costs.

Simple, long-stroke operations demanding very high nominal SPM.

For applications where the simplicity and high-speed blanking capability of a traditional pneumatic press are ideal, our TP-EX Series C frame pneumatic press offers a robust and cost-effective solution. We can also customize-make a Pneumatic Press. Available from 15Tons to 400Tons, the TP-EX Series provides the core benefits of pneumatic stamping press technology within a versatile C-frame structure, suitable for many standard stamping tasks requiring efficiency in high-volume production runs.

A Servo Stamping Press (also known as an Electric Servo Press) is an advanced type of stamping press that replaces the traditional flywheel, clutch, and brake system with a high-power servo motor (typically a permanent magnet synchronous motor).

Core Technology: The Electric Servo Drive

Drive Source: A high-power servo motor (typically a permanent magnet synchronous motor).

Power Transmission: The servo motor directly drives (or via a reducer, timing belt/gears) a ball screw or linkage mechanism (like a toggle type), moving the slide. This eliminates the flywheel and traditional clutch/brake system.

Motion Control: Fully digital programmable control. The servo system precisely governs slide position, speed, and acceleration, enabling any desired motion profile (e.g., slow approach, rapid stamping, dwell, slow return). Energy is supplied “on-demand” by the servo motor in real-time.

Programmable Curves (Core Advantage!): Tailor the slide motion on the HMI for specific materials and processes. Examples include:

Slow Approach/Contact: Reduces impact/noise, increasing die life.

High-Speed Stamping: Maintains productivity.

Bottom Dead Center (BDC) Dwell: Enables forming, coining, or rebound control.

Slow Return: Prevents material sticking or tearing.

Multi-Speed Control: Achieve multiple speed changes within a single stroke.

Variable Stroke Length: Set virtually any stroke length within the servo motor’s capacity – no hardware changes needed, drastically reducing setup time.

Precise Speed Control: Set maximum speeds, zone-specific speeds, and acceleration/deceleration rates.

Ultimate Flexibility: One machine adapts to numerous complex processes through programming. The NB-EX Series Servo Press excels here, offering unparalleled adaptability within its 15T-300T range.

Exceptional Repeatability: Ultra-high repeat positioning accuracy (±0.01mm or better) achieved via closed-loop feedback (encoder) constantly monitoring and adjusting slide position.

Stable BDC: Outstanding stability unaffected by load/speed variations, critical for precision forming.

Accurate Tonnage Control: Precise motor torque control enables fine tonnage management and monitoring, even constant-force stamping, protecting dies and parts.

Smart Control: Integrated advanced PLC/CNC systems allow complex programming, parameter monitoring, diagnostics, and data logging.

Optimized Effective SPM: While peak SPM might be slightly lower than top pneumatic stamping presses on long strokes, programmable motion significantly boosts effective output:

Achieve high effective SPM in short-stroke applications by optimizing curves (e.g., faster return).

Reduce/eliminate secondary operations (e.g., blanking + forming + coining in one stroke).

Minimal setup time (simply load the program).

Overall Efficiency: For complex forming, multi-process integration, or frequent job changes, the electric servo press delivers far greater overall productivity than pneumatic counterparts. The NB-EX Series is designed for maximum uptime and throughput.

Energy-On-Demand (Core Advantage!): Consumes electricity only during slide movement, proportional to the work done (tonnage * distance). Standby power is minimal (control system only).

No Flywheel Idling Loss: Eliminates the largest source of standby energy waste.

No Pneumatic Clutch: Saves compressed air consumption.

Proven Savings: Typically 30%-70% more energy-efficient than pneumatic stamping presses, depending on the process and utilization.

Reduced Noise & Vibration: Optimized motion (e.g., slow contact), no clutch engagement, and no massive flywheel result in drastically lower noise/vibration and a better work environment.

Longer Die Life: Programmable slow approach, dwell, and slow return dramatically reduce impact loads and die stress.

Optimized Material Flow: Precise speed/position control ensures smoother material flow during forming, minimizing defects (e.g., uniform stretching, controlled springback) and significantly increasing yield for complex parts.

High Precision & Stability: Guarantees highly consistent part dimensions, a hallmark of the NB-EX Series Servo Stamping Press.

Streamlined Design: Key components are the servo motor, reducer (optional), ball screw, or direct drive/linkage. Complex flywheel, clutch, and brake systems are removed.

Easier Maintenance: Fewer moving parts. Primary maintenance involves motor (often maintenance-free), screw/guideway lubrication, or bearings. Maintenance workload is significantly reduced.

Reduced Maintenance Costs: Fewer wear parts lead to substantially lower long-term costs compared to pneumatic stamping presses.

Higher Initial Investment: High-power servo motors, drives, precision components, and advanced controls make the purchase price higher than equivalent pneumatic stamping presses (often 1.5x – 2.5x+).

Strong TCO Advantage (Core Advantage!): Dramatically lower energy costs, reduced maintenance, extended die life, higher yield, and increased productivity mean the electric servo press typically offers a lower Total Cost of Ownership (TCO) over the medium-to-long term.

Complex Forming: Deep drawing, ironing, sizing, coining, flanging, tapping – processes demanding precise motion control.

Precision Stamping: Parts requiring high dimensional accuracy and BDC stability (e.g., connectors, lead frames, precision components).

Multi-Process Integration: Performing blanking, forming, coining, etc., in one machine cycle.

High-Mix/Low-Volume Production: Where rapid job changeovers and program switching are critical.

Challenging Materials: High-strength steel, magnesium, titanium, precision alloys.

Environments with strict noise, vibration, or energy consumption requirements.

Fill out the form below, and we will be in touch shortly.