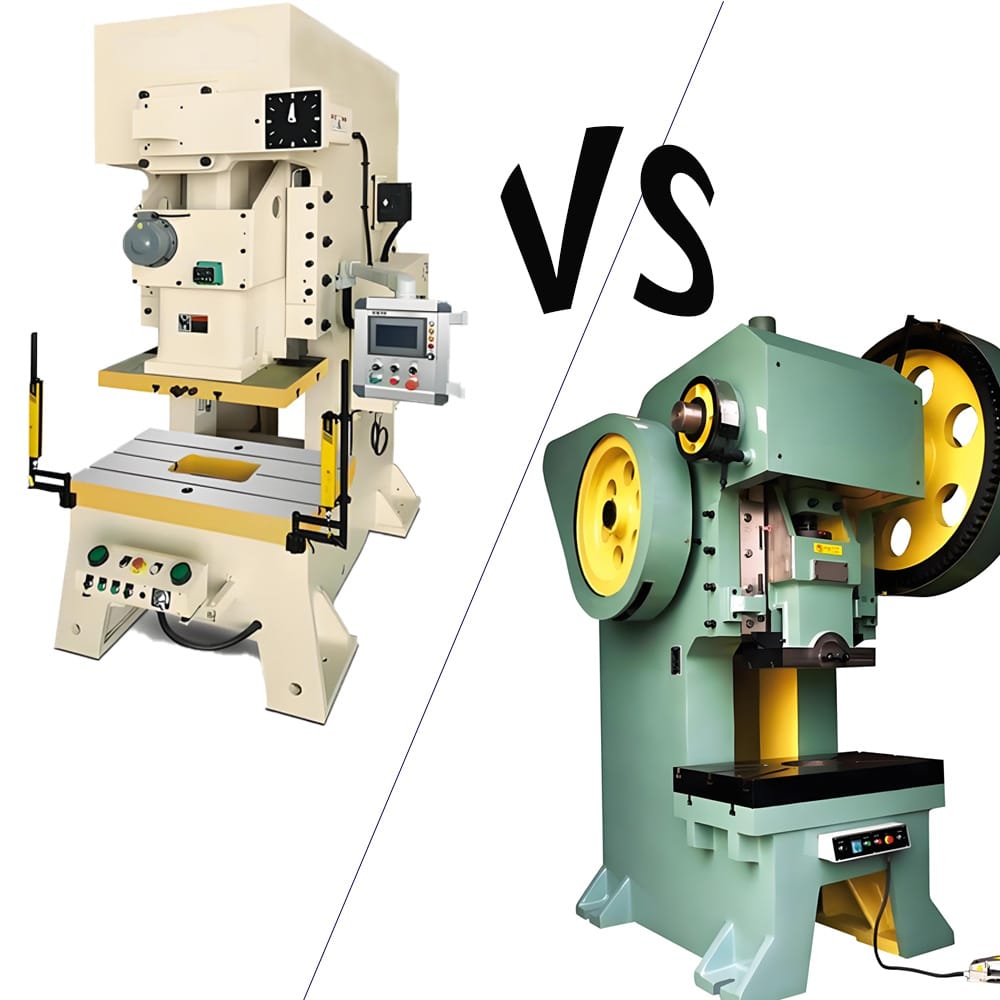

Two main machines stamp metal parts in factories: Mechanical Presses (old-school) and Servo Presses (high-tech).

Mechanical Press: Good for “brute force” tasks, like stamping thick metal sheets or simple parts.

Servo Press: Perfect for “precision work,” like smartphone components or medical devices. Plus, it saves energy!

How it works:

Uses a heavy flywheel that spins non-stop. Even when idle, it wastes energy!

Downsides:

Fixed speed (one rhythm only).

Noisy (like a tractor) and less precise (error ≈ thickness of a human hair).

How it works:

Uses a motor to control the stamping action directly. Starts/stops instantly—no energy waste!

Pros:

Super precise (error ≈ 1/10th of a hair’s thickness).

Saves 30-60% on electricity—cuts yearly bills by thousands!

Feature | Servo Presses | Mechanical Presses |

|---|---|---|

Precision |

Super high (perfect for smartphone parts) |

Basic (good enough for rough work) |

Speed |

Adjustable (fast/slow, programmable) |

Fixed speed (one setting) |

Energy Use |

Efficient (no power waste) |

Wastes energy (flywheel spins non-stop) |

Noise |

Quiet (like an AC) |

Loud (like a drill) |

Price |

Expensive (saves money long-term) |

Cheap (budget-friendly) |

You make precision parts (electronics, medical tools).

You want to save on electricity (it pays off in 2-3 years).

You need flexibility (frequent mold changes or adjustments).

You do simple jobs (cutting metal sheets, basic stamping).

You’re on a tight budget.

Energy costs are low in your area.

No! Modern servo presses (e.g., 300-ton models) are as strong as mechanical ones but with precise control.

Not yet! They’re still cost-effective for simple tasks, but servo is taking over precision industries.

Easier! No clutch or brake parts to replace—lower maintenance costs.

👉 [Click here for a free consultation] with an engineer!

Fill out the form below, and we will be in touch shortly.