Amongst the modern technologies driving this development is the turret strike press– a cornerstone of contemporary sheet metal construction. Yet how does it work, and why is it increasingly combined with innovative systems like servo press machines and CNC turret punching devices? In this guide, we’ll check out the mechanics, applications, and advantages of modern turret punch technology, with a focus on its synergy with servo-driven systems and CNC automation.

A turret punch press is a specialized machine made for high-speed punching, developing, and reducing sheet steel. Its defining function is a revolving turret that holds numerous punch-and-die collections, making it possible for rapid tool adjustments without hand-operated intervention. This modern technology has become crucial in sectors like automotive, aerospace, and electronic devices, where complex forms and limited resistances are regular.

As producers change towards smarter, greener remedies, turret punch presses have actually evolved. Modern versions, such as CNC turret punching machines and servo press-driven systems, currently control the market, using unparalleled accuracy and energy efficiency. Let’s dive deeper right into how these devices work and why they’re changing sheet steel construction.

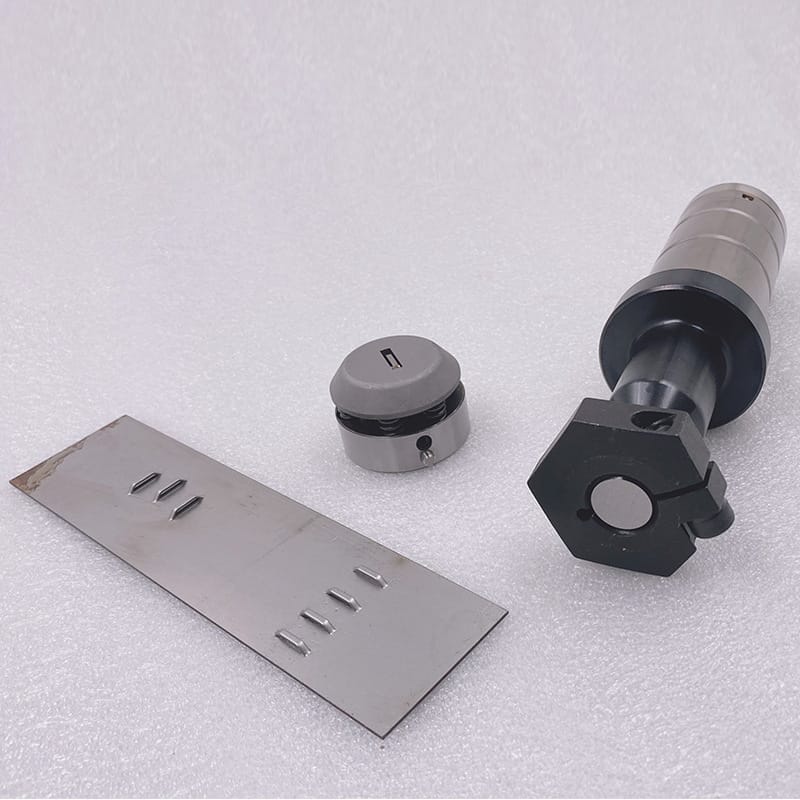

At its core, a turret punch press automates the procedure of creating openings, slots, and elaborate patterns in sheet metal. The maker’s turning turret (commonly top and lower) houses loads of tools, allowing it to switch between operations effortlessly. Key elements consist of:

Turret: Holds punch and die collections for varied operations.

CNC Control System: Programs toolpaths and maximizes production (crucial for CNC turret punching machines).

Worktable: Safeguard the sheet steel turret press product throughout machining.

Unlike traditional single-tool presses, turret punch modern technology masters high-mix, low-volume production– optimal for personalized sheet steel turret punch tasks like units, brackets, or attractive panels.

The assimilation of CNC (Computer Numerical Control) has actually changed turret punch presses into accuracy giants. A CNC turret punching machine utilizes programmed directions to regulate tool motion, speed, and force, guaranteeing repeatability across hundreds of parts.

Why CNC Issues:

Precision: Accomplish tolerances as tight as ± 0.1 mm, essential for aerospace or clinical components.

Rate: CNC automation lowers cycle times by maximizing toolpaths.

Flexibility: Easily reprogram the machine for new designs, ideal for prototyping.

For instance, a sheet metal turret press outfitted with CNC can switch from punching ventilation holes to embossing logo designs in seconds– jobs that would certainly take hours by hand.

While CNC handles the “mind” of operations, servo press equipment supplies the “muscle.” Unlike typical hydraulic or pneumatically-driven systems, servo-driven presses use programmable electric motors to control ram rate, stroke, and pressure with determined accuracy.

Advantages of Servo Press Assimilation:

Energy Efficiency: Servo motors eat power only throughout active cycles, lowering power costs by up to 30%.

Lowered Sound: Quieter procedure enhances work environment conditions.

Flexible Efficiency: Change parameters in real-time for products like stainless steel or aluminum.

Combining a servo press with a CNC turret punching device creates a “smart” system. For instance, in sheet metal turret punch production, the servo electric motor can modulate force to stay clear of material contortion, also at high speeds.

From commercial equipment to consumer gadgets, turret punch presses form the globe around us. Common uses include:

Electronic devices: Producing framework, warmth sinks, and port plates.

Automotive: Creating body panels, braces, and EV battery parts.

Style: Making attractive façades and HVAC ducting.

A sheet steel turret press radiates in these applications due to its ability to manage diverse materials– from slim aluminum sheets to thick stainless steel– without retooling.

Just how does a turret punch press outmatch older mechanical or hydraulic presses?

Multi-Tool Flexibility: Standard presses require hands-on die modifications; turret systems automate this.

Accuracy: CNC eliminates human error in alignment.

Cost-Effectiveness: Servo-driven systems lower waste and energy costs.

For companies focusing on sustainability and agility, CNC turret punching equipment coupled with servo press innovation is the clear selection.

Choosing the ideal machine relies on your demands:

Product Type/Thickness: Make sure the sheet metal turret punch can manage your work (e.g., 6mm moderate steel vs. 1mm copper).

Production Quantity: High-volume runs take advantage of CNC automation.

Modern technology: Choose servo press machines for energy savings and accuracy.

At FUTIAN, we concentrate on CNC turret punching machines tailored to your market. Explore our servo-driven solutions for unequaled efficiency.

The future of turret strike press modern technology is brilliant:

IoT Assimilation: Monitor machine wellness and optimize workflows remotely.

Eco-Friendly Designs: Servo press equipment will certainly drive greener production.

Advanced Tooling: Coatings and geometries for reducing compounds and alloys.

The turret punch press is more than a tool– it’s an entrance to smarter, quicker, and a lot more sustainable manufacturing. By incorporating CNC turret punching machines with servo press systems, businesses can tackle complicated sheet steel turret press tasks with confidence.

Ready to elevate your production line? Discover our variety of advanced servo press equipment and CNC turret punching equipment made for accuracy and performance. [Call us today] to read more!

Fill out the form below, and we will be in touch shortly.